Finish

Posted by:

gabriele schieda

(---.google.com) Date: August 13, 2015 10:11PM

Hi everyone I have noticed that on the dryer 9 rpm the finish ends up on the ends and forms a hump in the middle. Like a bow tie. I put it on and its perfect and slowly it ends up that way. Thank you

Re: Finish

Posted by:

Bruce Johnstone

(---.cpe.cableone.net) Date: August 13, 2015 11:01PM

You may be putting on too much. My drier turns at 7-8 rpm and the epoxy levels out nicely.

Re: Finish

Posted by:

Roger Templon

(---.aoo.pa.atlanticbb.net) Date: August 14, 2015 05:54AM

gabriele

i also think you may be applying too much finish. i have a variable speed motor that i dial down to approximately 6 - 8 rpm and have no problem with uneven buildup of the finish anywhere on the wraps.

Re: Finish

Posted by:

Bill Sidney

(---.gci.net) Date: August 14, 2015 10:35AM

make sure your rods are level not high on one end , your finish is to stiff when you apply it , or like they said before to much finish at one time

William Sidney

AK

Re: Finish

Posted by:

Mark Hahn

(---.bop.gov) Date: August 14, 2015 12:13PM

I've made the same mistake, putting on too much finish with the same RPM you are using. Problem solved when I used less finish. Darn the learning curve.

Re: Finish

Posted by:

Jay Dubay

(---.try.wideopenwest.com) Date: August 14, 2015 12:36PM

I use 2 thin coats, I build fresh water rods and really watch how thick my epoxy is as I don't want to compromise the blank action with alot of epoxy weight especially the front half. It makes me cringe when I see a high quality blank with epoxy footballs on the guide wraps. Tight Lines!! Jaa

Re: Finish

Posted by:

Capt. Michael Harmon

(107.77.76.---) Date: August 14, 2015 12:40PM

I agree with above. Too much finish. Apply more than one coat and apply thin coats. Press the first coat into the wraps to fill gaps and let dry. Then apply one or more additional coats to build it. Also use heat to work out air bubbles. I use a minimum of two coats and up to five coats on rods. Best MH

Re: Finish

Posted by:

roger wilson

(---.hsd1.mn.comcast.net) Date: August 14, 2015 01:36PM

I typically use one + coat of finish. I will apply a coat of finish quickly on all of the wraps and guide feet. Then I go back to the beginning and use a bit of heat to help thin, level and otherwise remedy any defects that might be found on guides or wraps. At this time if there is any excess finish, it is wicked off with a brush. Then, I will go back one more time to check for any thin spots or high spots and either add or subtract finish from the area as needed with the help of moderate heat.

I keep a close eye on the rod for the first 10-15 minutes of drying to insure that no high or low spots have developed. If they do, I will subtract or add finish as needed and then just let it dry. I will ship the next morning. I do all of my inspections under very intense light and magnification.

Take care

Re: Finish

Posted by:

Capt. Michael Harmon

(---.dyn.optonline.net) Date: August 14, 2015 04:18PM

Hey Roger, which brand of finish do you use for your rods? Thx MH

Re: Finish

Posted by:

roger wilson

(---.hsd1.mn.comcast.net) Date: August 14, 2015 07:06PM

Michael,

I use Flex Coat high build.

Be safe

Re: Finish

Posted by:

bill boettcher

(---.nwrknj.fios.verizon.net) Date: August 14, 2015 07:27PM

Easy thing to do

Apply finish

Then stop the turner and let excess drip off and grab the drops with your brush

Turn the turner back on

Too much finish

Bill - willierods.com

Re: Finish

Posted by:

gabriele schieda

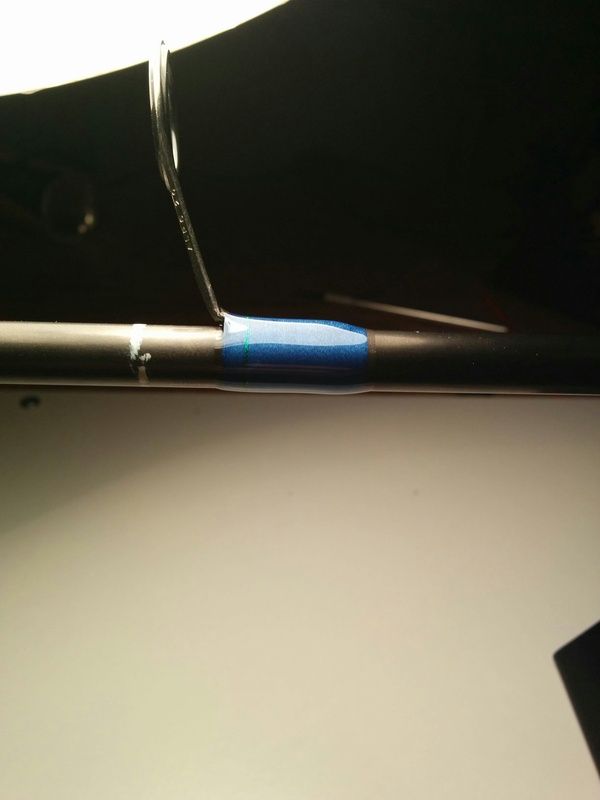

(---.google.com) Date: August 15, 2015 04:12PM

Re: Finish

Posted by:

bill boettcher

(---.nwrknj.fios.verizon.net) Date: August 17, 2015 05:39PM

That does not look bad at all ???

Bill - willierods.com

Re: Finish

Posted by:

Nate Nelson

(---.hsd1.mn.comcast.net) Date: August 17, 2015 06:16PM

I agree with Bill. Most of my finish looks exactly the same as what you have there

Re: Finish

Posted by:

gabriele schieda

(---.google.com) Date: August 17, 2015 10:55PM

Thank u guys I guess I am being to picky. Thanks for all your help.

Re: Finish

Posted by:

eric zamora

(---.lightspeed.frsnca.sbcglobal.net) Date: August 18, 2015 11:03AM

Dang, you're good! :) i was imagining something i've seen in the past but yes, your finish looks good. i wonder about the entrance to the "tunnel" area, is there space there without finish where the guide foot first meets the blank?

eric

fresno, ca.

Re: Finish

Posted by:

bill boettcher

(---.nwrknj.fios.verizon.net) Date: August 18, 2015 02:17PM

I saw that just didn't say That should be filled with finish You could also learn the Forhan locking wrap for the single foot guides Keeps them from being pulled out

Bill - willierods.com

Re: Finish

Posted by:

gabriele schieda

(---.google.com) Date: August 18, 2015 09:23PM

What I always do is put a drop of finish in front with a needle and put the rod upright.

Re: Finish

Posted by:

gabriele schieda

(---.google.com) Date: August 18, 2015 09:23PM

What I always do is put a drop of finish in front with a needle and put the rod upright.

Re: Finish

Posted by:

gabriele schieda

(---.google.com) Date: August 18, 2015 09:23PM

What I always do is put a drop of finish in front with a needle and put the rod upright.

Sorry, only registered users may post in this forum.

|