Guides moving during static load

Posted by:

Ryan Edamatsu

(---) Date: January 05, 2024 12:43AM

I am trying to do a static load test of the guide placements on a 7 foot medium heavy casting rod. I attached a reel and threaded the line, then loading the rod by pulling on the line. My guides are taped on and they move to the side under load. It was getting difficult to get accurate and reliable outcomes when the guides are constantly shifting under load. Having to readjust the guides repeatedly greatly prolong the testing time. How do you keep the guides from moving around and doing the static test effectively?

Re: Guides moving during static load

Posted by:

Al purvis

(---.res6.spectrum.com) Date: January 05, 2024 01:43AM

I use these: [ mudhole.com]

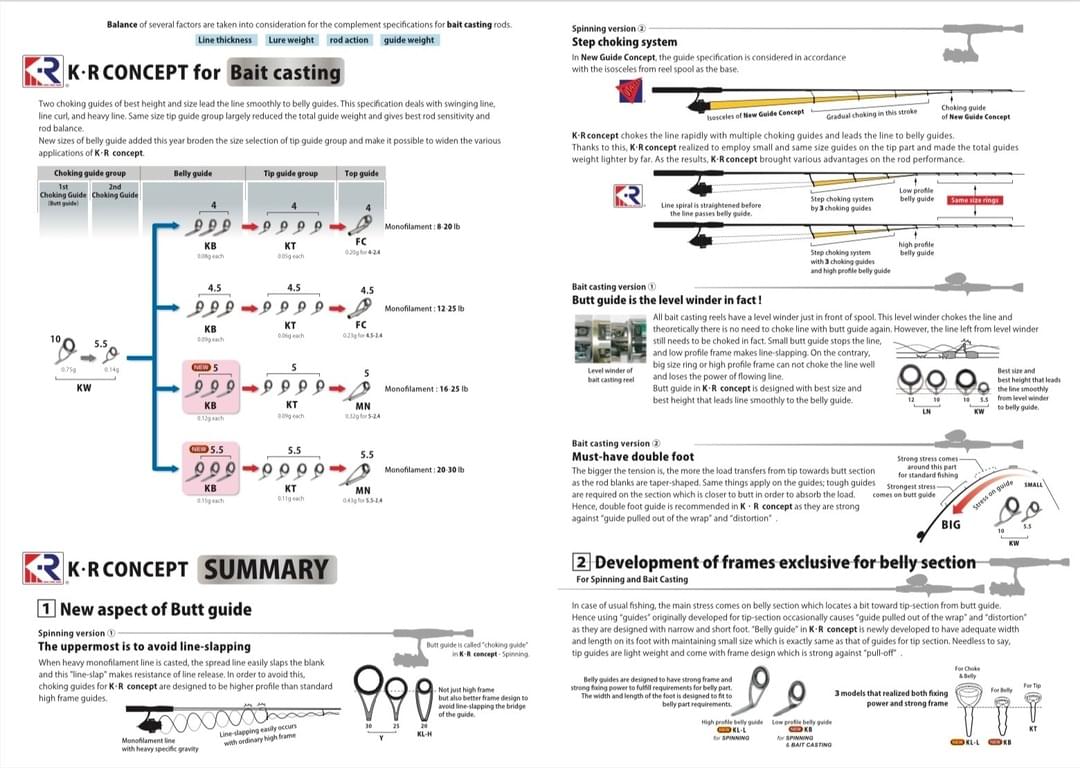

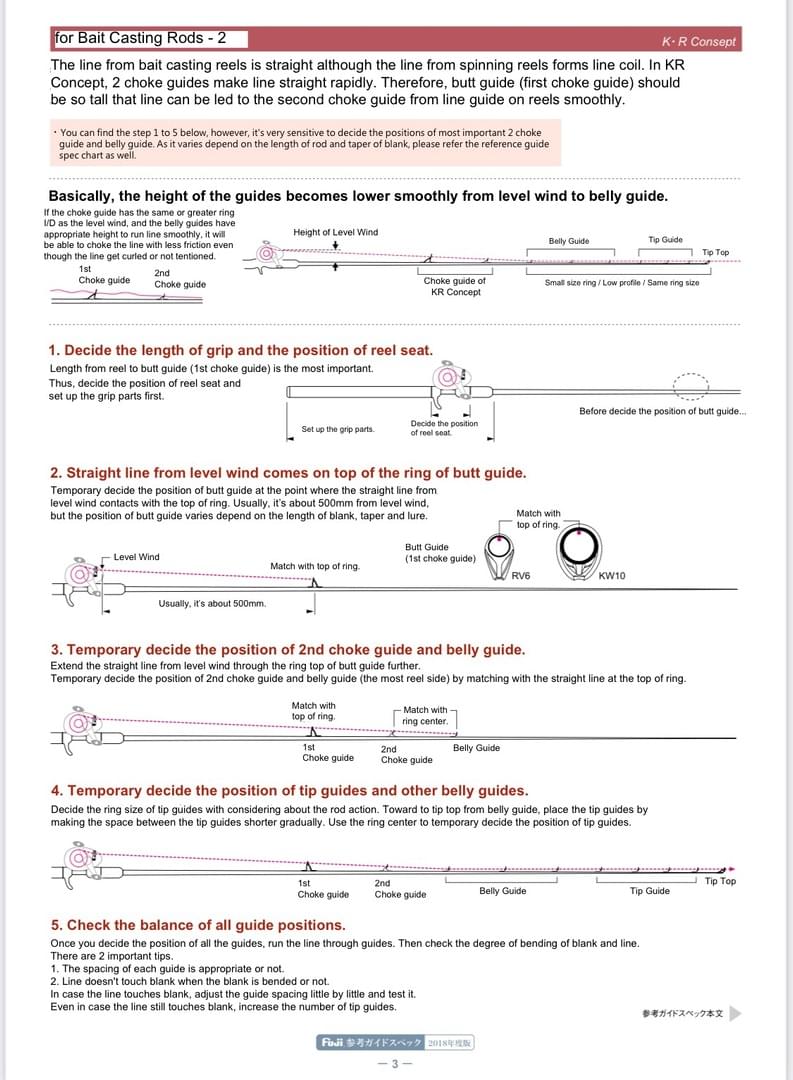

Also, on conventional builds I have started learning the Fuji kr concept which takes the guess work out of half the guides and leaves you with your runners to figure out spacing.

I also will use spare thread to secure guides temporarily and I wrap the thread in a way that I can unravel it easily. With enough tension you can hold a guide in place more than well enough with only a few wraps to do your final static test/test casting.

Re: Guides moving during static load

Posted by:

Michael Danek

(---.alma.mi.frontiernet.net) Date: January 05, 2024 07:02AM

The CRB devices that Al recommends work well for the smaller diameter areas of the blank-I often use two of them for each guide. Bigger O rings work well for the rest of the blank, or tape. But the biggest aid is to use the two line method for the stressing of the blank. This means that the guides will not be taking the load of the rod so will stay put better. They also can be moved without unloading the rod, which is very convenient.

The method can be found here: [ anglersresource.net] or in the library right on this site: [ www.rodbuilding.org]

The line to the tiptop loads the rod, and the line through the guides needs only a little weight on it to keep just a little tension on that line.

Re: Guides moving during static load

Posted by:

Michael Danek

(---.alma.mi.frontiernet.net) Date: January 05, 2024 07:10AM

Maybe Herb Ladeheim will repeat his posting on how he does it with the line going through O rings and not the guides. I have not yet tried it but am going to on my next build. I think it might be the ultimate solution to placing guides properly with one line and having no problems with the guides moving, while allowing them to be moved as desired.

Re: Guides moving during static load

Posted by:

Mark Hahn

(---.29.18.98.static.ip.windstream.net) Date: January 05, 2024 10:23AM

Michael is right. This method works great to keep the stress off the guides. It works well for all types but especially for casting guides on top of the rod.

Re: Guides moving during static load

Posted by:

Norman Miller

(Moderator) Date: January 05, 2024 10:51AM

Use the two line static test. Run the line though the guides tie on a light weight a let it hang from the tip. Now tie another line to the tip top and then tie it to an immovable object. Now you can put a bend in the rod without the guides rotating to one side.

[ www.rodbuilding.org]

Norm

Re: Guides moving during static load

Posted by:

Kerry Hansen

(---.wavecable.com) Date: January 05, 2024 11:55AM

History of the two line method is a young Australian kid suggested this method back in the 1970's-80's I believe. run one line thru the guides with a very little wt on end to take up slack and a second line attached to fixed TIPTOP with a heavy weight on it.

Re: Guides moving during static load

Posted by:

Herb Ladenheim

(94.140.11.---) Date: January 05, 2024 08:56PM

Hey guys -

I developed the "O" ring system to be used with fly rods.

You can also use it with spinning rods once you determine the position of the stripper guide per the diameter of the rssl spool.

One could probably use the "O" rings on a conventional casting rod - but not the amunt of guides needed to keep the line off the blank.

But if you somehow determined the number of guides - flip the blank upside down with guides on the bottom - spread the "O" rings to give a nice curve - favoring the tip area with more guides.

But it seems to me that the 2 line system mentioned by Kerry is the way to go for other than fly or spin rods.

Herb

Edited 1 time(s). Last edit at 01/06/2024 09:42AM by Herb Ladenheim.

Re: Guides moving during static load

Posted by:

Tim Scott

(---) Date: January 06, 2024 08:32AM

I use the small orings on blank, but an extra on, glue tip then position guides. Orings cut off as I wrap.

Re: Guides moving during static load

Posted by:

Herb Ladenheim

(94.140.11.---) Date: January 06, 2024 09:45AM

Tim Scott Wrote:

-------------------------------------------------------

> I use the small orings on blank, but an extra on,

> glue tip then position guides. Orings cut off as

> I wrap.

Tim,

It seems as though you are using the "O" rings to hold the guides. I am not - I use them in place of the guides. Then I mark the blank when I am happy with the line curve.

Herb

Re: Guides moving during static load

Posted by:

Mark Brassett

(---) Date: January 06, 2024 10:20AM

Herb, how are you threading the line through the rings?

Re: Guides moving during static load

Posted by:

Ryan Edamatsu

(---) Date: January 10, 2024 03:07PM

I only know of the kr concept for spinning rods. How do I do the kr concept for casting rods?

Re: Guides moving during static load

Posted by:

Michael Tarr

(---) Date: January 10, 2024 03:30PM

Re: Guides moving during static load

Posted by:

Michael Tarr

(---) Date: January 10, 2024 03:33PM

Re: Guides moving during static load

Posted by:

roger wilson

(---) Date: January 11, 2024 07:02PM

Ryan,

Don't overthink this situation.

If you have a conventional casting rod setup, just turn the rod upside down for the static testing.

This puts the line below the guides and the pull is a straight downward pull when doing stress test.

Re: Guides moving during static load

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 12, 2024 01:21PM

If you are doing a static load guide placement on a conventionally wrapped casting rod, why would you want to just turn the rod upside down? You're not going to be able to tell if the line will be touching the blank, which some people don't mind, but you also aren't going to be able to tell if the line goes below the blank, which you definitely don't want to happen. You don't want to over think the situation, but you need to think about it correctly.

Do it with the rod facing the correct way, and use the two line static method that has been mentioned many times already. I use the tubing that Mud Hole offers to hold the guides on while placing them and wrapping them. It comes in 4 different sizes and you can cut your bands to any width you'd like.

It's easy to do.

Re: Guides moving during static load

Posted by:

Ernie Blum

(---) Date: January 12, 2024 03:47PM

Herb Ladenheim Wrote:

-------------------------------------------------------

> I developed the "O" ring system to be used with

> fly rods.

Herb,

Is this technique described anywhere on this board?

Re: Guides moving during static load

Posted by:

Ryan Edamatsu

(---) Date: January 15, 2024 07:53PM

It looks like I won't be able to set up a KR concept layout as I will have to order a completely different set of guides with the recommended ring sizes for a KR build.

I have set up my 7 foot rod for a 9 guide layout. I attempted to place the guides according to the 2 line static test and I was able to get it to the point the line is almost touching the blank. Maybe even touching the blank in some places. This was when loaded to near 90? bend. I hope I'm on the right track since I didn't want to add any more guides.

When you do the static load, are you looking for a spacing where the line doesn't touch the blank? Or barely touching when near 90? load? It seems I had some struggles as I was looking for the best spacing where the line doesn't make contact with the blank. Maybe I'm actually looking for the wrong results?

Re: Guides moving during static load

Posted by:

Ryan Edamatsu

(---) Date: January 21, 2024 03:05PM

When doing static load on conventionally wrapped casting rods, really what do I look for? Should I be looking for a spacing where the line doesn't touch the blank when under large load?

I tried some static loads and I was able to get it to the point where the line almost touches the blank. It may be touching the blank at some places, but lightly. It is a 7 foot medium-heavy casting rod, and I plan to use 9 guides +tip. Any feedback is appreciated.

Re: Guides moving during static load

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 21, 2024 06:16PM

Ryan, the type of spacing you're talking about to keep the line where it almost touches the blank, is the type of spacing I use on my casting rods, so I would say that's the type of spacing you're looking for. As far as questioning how much load you want to use when spacing guides goes ..... I use a load large enough to deflect the blank 1/3 of its' total length. Just as if I were CCS testing the blank for IP.

So if you're not familiar, you have the rod set up in a device to hold it horizontally, you'd measure the distance from the tip of the rod to the floor, lets say it's 48". It's a 7' rod so 1/3 of 84" is 28". You'd then hang enough weight from the tip of the rod to bring the tip of the rod to 20" from the floor. And then use the two line testing method to place your guides.

There is more to setting the rod up if you were doing a CCS IP test, but as long as you aren't supporting the rod ahead of the reel seat, you'll be fine.

As far as number of guides you plan to use, if you like your line path in relationship to the blank, then that's enough guides. I don't know how tall or what size guides you're using, I will just say that I personally haven't used less than 10 guides + tip top on any of the rods I've built that are between 6' 6" to 7' long. I'm not saying you should. It's just the way its worked out for me.

If I'm even a little iffy on spacing, I will always add an extra guide. The way I see it, with the size guides I use, I'm adding a very minimal amount of weight, but I am helping to protect the blank against some potential poor fish landing decisions.

Edited 3 time(s). Last edit at 01/21/2024 06:21PM by David Baylor.

Sorry, only registered users may post in this forum.

|