Ready to throw in the towel

Posted by:

Al purvis

(---) Date: April 17, 2023 10:59PM

Hey everyone,

I’ve posted a lot on this subject on this forum and i apologize in advance if I am beating a dead horse on this and if I sound like I’m whining.

I am having a nightmare of a time with making my own grips all because of the cork inlet section. To elaborate, I can get a grip with no glue lines, shape perfectly and evenly with no issue, but when it comes to having even walls around the reel seat hood of my fly rods I always have the issue I pictured. In case it doesn’t show here it is: [ imgur.com]

I have tried both shaping the grip on a mandrel and on the rod blank directly. The same issue keeps happening. I prefer to do the mandrel way so I have stocked up a good collection of different sized mandrels and can get close in size to the rod blanks I build on.

To elaborate on my process: I modify a hole saw to fit my inlet size (thanks to herb for the idea) and then drill the cork out to be able to fit on a threaded rod that’s exactly the same diameter as my mandrel, glue the cork rings and clamp, switch the grip to the mandrel, use a half round file to rough shape the grip to an even and concentric shape to the mandrel (I verify this with a caliper) by slowly knocking off the high spots, but without fail the inlet section always ends up off before I even begin shaping. What’s even more strange to me is that if I measure with my caliper at the top of the grip from the outside of the cork ring to the drilled hole in the center, I have even measurements all around. Something goes sideways when I get to the inlet section on the grip.

I really don’t want to buy premade grips anymore but alternatively, I’m tired of throwing money and cork away just to keep running into the same issue. It doesn’t help I am ocd either but speaking out of frustration, it makes me want to throw in the towel on this thing all together! Does anyone have any idea on what I’m missing or doing wrong?

Re: Ready to throw in the towel

Posted by:

Phil Erickson

(---) Date: April 17, 2023 11:12PM

If I read this correctly, you are cutting out the inlet before you turn the grip. If so, you are shaping on the inlet section that has no mandrel support, thus it flexes as you shape it. I cut out the inlet after shaping using a Forstner bit slightly smaller and finish with a Dremel small sanding drum.

If you need to make the recess before turning, how about making a smal wood or cork plug for the recess that you remove when done shaping.

Re: Ready to throw in the towel

Posted by:

Spencer Phipps

(---) Date: April 18, 2023 12:45AM

Not sure it is possible to make anything true and concetric with using wood lathe turning tools. Frankly I say well done, considering your tools.

Re: Ready to throw in the towel

Posted by:

Al purvis

(---.res6.spectrum.com) Date: April 18, 2023 12:50AM

Phil,

I leave the reel seat hood in the inlet when shaping it. I have not yet glued it to the reel seat.

Re: Ready to throw in the towel

Posted by:

Stan Vogel

(---) Date: April 18, 2023 06:55AM

Flex coat has a video showing how they do it, it's worth a look.

Re: Ready to throw in the towel

Posted by:

Daryl Ferguson

(---) Date: April 18, 2023 07:34AM

I concur with Stan. The Flex coat video might be worth a watch.

Re: Ready to throw in the towel

Posted by:

Matt Ruggie

(---) Date: April 18, 2023 08:50AM

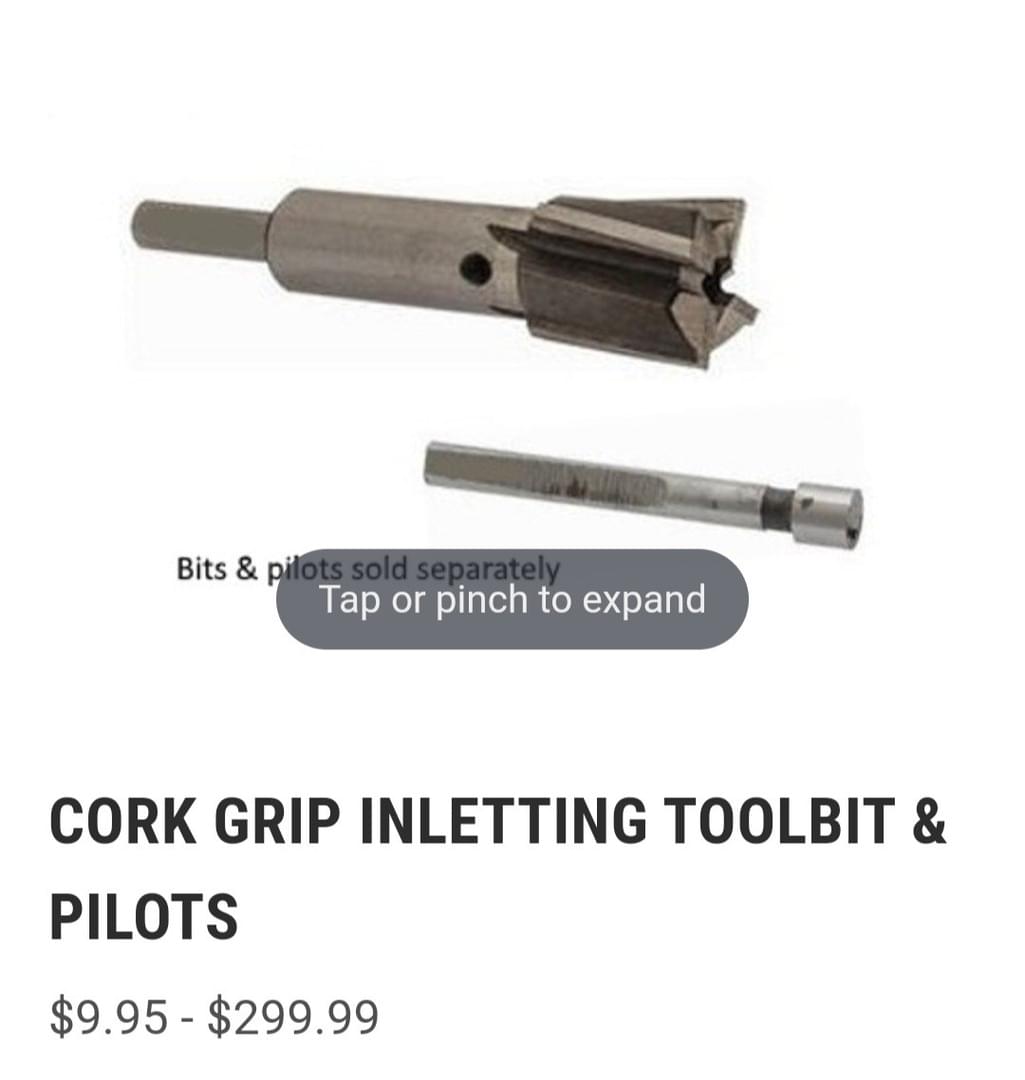

Drill it out after like Phil describes with a forster bit. Or if ya need to go deeper I'll use a pen barrel trimming bit and clean up the hole and fine tune the size with a dremel. They used to make the crafty cutter bit for inleting but i havent seen them advertised lately. I believe I saw a new style out but IIRC it was very pricey

Re: Ready to throw in the towel

Posted by:

Matt Ruggie

(---) Date: April 18, 2023 08:57AM

Re: Ready to throw in the towel

Posted by:

Tom Kirkman

(Moderator) Date: April 18, 2023 09:21AM

You have a couple of options here. The first is the easiest - stop using seats that require burying the forward hood. The second is to bore a single ring to the correct size for the inlet and then glue that ring onto your other rings on the mandrel. To ensure you have it concentric on the mandrel to start with, you have to build up a section on the mandrel to accept that large bored ring. This is really a very simple process. From there, everything turns down the same and all will be concentric with the mandrel and the large bored ring will be concentric with the rest of the handle.

...........

Re: Ready to throw in the towel

Posted by:

Richard Bowers

(---.ptld.qwest.net) Date: April 18, 2023 10:32AM

There are drill bits specifically designed for this purpose. It looks like a Forstner bit with a 1/4" post extending from the front. The post guides the bit precisely and the result is a perfectly centered inlet. Another option is a Crafty's Cutter (From Dan Craft Enterprises) if you can find one. I have one and it works extremely well, as long as you have the ability to use high speed (3500+ RPM) Lower speeds tend to create divots in the cork.

Re: Ready to throw in the towel

Posted by:

John Cates

(Moderator) Date: April 18, 2023 10:55AM

Hello all. Evidently the horse isn't dead yet. Consider this the death blow.

[ www.youtube.com]

Available at many of our dealers as well as flexcoat.com

[ flexcoat.com]

Flex Coat Company

Professional Rod Building Supplies

www.flexcoat.com

Re: Ready to throw in the towel

Posted by:

Michael Danek

(---.alma.mi.frontiernet.net) Date: April 18, 2023 11:22AM

Good stuff from Flex Coat, as usual. thanks!

Here is the recess fly grip video: [ flexcoat.com]

Edited 1 time(s). Last edit at 04/18/2023 11:23AM by Michael Danek.

Re: Ready to throw in the towel

Posted by:

Herb Ladenheim

(45.88.190.---) Date: April 18, 2023 01:11PM

Please call me late this afternoon or eary evening. I'd like to know what all those layers are in the picture.

Obviously they are not concentric. Let's see if we can figure it out.

Herb

Re: Ready to throw in the towel

Posted by:

Donald La Mar

(---) Date: April 18, 2023 03:51PM

Al

I build mostly fly rods and turn the grips on a 1/4" mandrel. Then, BEFORE boring the inside grip diameter to fit the blank, use one of these - [ mudhole.com] - to bore the inlet for the hood. It's hard for the hood inlet to not be concentric with the grip's bore.

Re: Ready to throw in the towel

Posted by:

Tom Kirkman

(Moderator) Date: April 18, 2023 04:00PM

At the Expo I mentioned to Roger that I thought his reverse pilot bit cutters were about the most underrated rod building tool out there. You could certainly do it with one of those and everything would be perfectly concentric. Best of all, it'd take you no more than 30 seconds to do it, if even that.

...........

Re: Ready to throw in the towel

Posted by:

David Baylor

(---.res6.spectrum.com) Date: April 18, 2023 04:02PM

First off I would say that a hole saw isn't what I would consider a precision tool. They invariably have at least a little bit of wobble. You mentioned a modified hole saw? I'd be interested in what the modification is. I will say this about using a hole saw. If you want to make a hole saw a precision tool, and this may the modification you're speaking of, DO NOT use a drill bit as the centering rod for the hole saw. Use a 1/4" rod. If you use a drill bit the flukes will make the center hole bigger, and allow the hole saw to wobble even more than they already do. Use a 1/4 rod. The 1/4 rod will not make the center hole any larger. Also make sure the rod extends at least 1" into your material. The deeper it is into the material, the less it will wobble.

The Forstner bit like those described would work quite well, as well. But what I would try is one of the reverse pilot bits available from Flex Coat. Those things work awesome. I made a full length cork grip for one of my casting rods. Wanting to save myself a ton of time, work, and the headache of reaming that much cork, I used one of the reverse pilot bits to bore the center hole of the grip out to bring it closer to the OD of the blank I was going to be fitting it on.

Worked like a charm !!!!I

It would definitely be the route I would take, and I'm pretty sure it would cure the problem you're having. If Flex Coat doesn't offer a bit the size you need, I believe they have a video on how you can modify a regular spade bit to work the same way their bits do.

Re: Ready to throw in the towel

Posted by:

Matt Ruggie

(---) Date: April 18, 2023 05:03PM

Hole saw would not be my first choice..modified or not. But if your gonna use one, then David's spot on about the pilot bit. On the pen trimming bit I use a 1/4" rod.

Re: Ready to throw in the towel

Posted by:

Thomas Bell

(---) Date: April 18, 2023 05:18PM

Al, glue up cork on desired mandrel ( diameter as close to rod diameter as you can).

Shape grip. Get some nylon spacers from Ace Hardware to match this diameter. I usually use 3/8 mandrel.

Get a wood bit that matches the reel seat insert. Tape it to set drill depth.

Place the spacer on the pointy end of the bit. Insert spacer into grip, then slowly drill out.

Works great.

TJB

Re: Ready to throw in the towel

Posted by:

roger wilson

(---) Date: April 18, 2023 07:34PM

If you have access to a lathe, and if you have a good three bearing steady rest, this system works very very well to take care of your issue:

[ www.rodbuilding.org]

Go ahead and finish your grip to the way you want it finished.

Then, chuck the grip into the head stock chuck with a full circle chuck.

Clasp the end that needs to be bored into the 3 bearing steady rest.

Then, take your bit of choice and chuck it into the tail stock of the wood lathe.

With the grip turning at a medium to medium high speed, advance the bit, (what ever form that it is) into the end of the spinning grip.

Since the grip is spinning and the bit is stationary, there is no choice except to have a perfectly centered hole.

Best wishes.

p.s.

Note: you do not have to own the lathe or tooling. You just have to have access to such equipment.

Take care

Re: Ready to throw in the towel

Posted by:

Lynn Behler

(---.44.66.72.res-cmts.leh.ptd.net) Date: April 18, 2023 07:54PM

Most of what we really "need" to know can be learned from a Flex-Coat video.

Sorry, only registered users may post in this forum.

|