Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 10:20AM

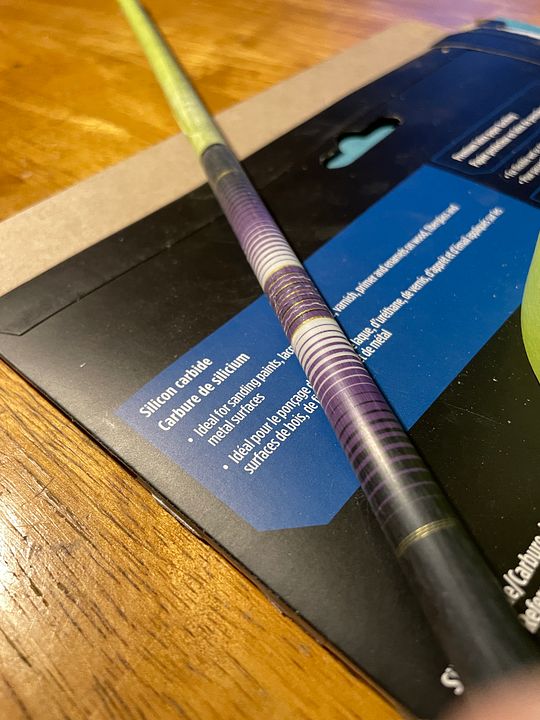

I've been obsessing over a couple of projects and the current step includes trying to get the epoxy on this switch rod to lay flat over the base wrap.

I've been to a point where I was calling it a done deal but knowing the base wrap, when viewed in certain lighting, had waves in the epoxy, well, it bothered me..

I had posted this pic the other day but it will serve here as my example of what I was calling "done".

But then I focused on the ripples and waves and I decided to sand it down and retry applying the epoxy to get a smoother result

I was pretty happy with the results of the sanding and was excited to reapply the epoxy. I decided to try a new technique to me which is to apply the low build epoxy by brush and apply it in a thin layer. After it set I could see the striations of the brush and it did not have that glassy look. I added a second coat in what to me is a more normal application with spatula and basically flooding the wrap, letting the epoxy drip off the bottom side before wicking it away, turning the rod 180 degrees for awhile after I was able to see the sags start and then flipping it again followed by an 8 rpm dryer. I think I fuss too much with it and it starts to set up and won't self level after a certain point. Fast forward to four coats later chasing my tail and chasing bubbles and fussing about. At one point it was so bad I knew it was not going to settle down. I stopped the dryer and I could see the epoxy still moving so I went back to the sit and flip method and it actually helped but the damage was done so to speak. The fourth coat helped more but essentially I have ended up right back where I started before sanding.

Is this normal? Is this an acceptable result? My son who also builds some rods says I'm being too fussy.

Thoughts?

Edited 1 time(s). Last edit at 02/21/2023 10:22AM by Bob Foster.

Re: Epoxy is hard (for me...)

Posted by:

Daryl Ferguson

(---) Date: February 21, 2023 11:41AM

I agree with your son, but yours is the only opinion that matters.

Re: Epoxy is hard (for me...)

Posted by:

Mark Brassett

(---) Date: February 21, 2023 11:44AM

I think it looks awesome.

Re: Epoxy is hard (for me...)

Posted by:

Les Cline

(---) Date: February 21, 2023 11:46AM

Bob,

First off, that is some very detailed threadwork! Your fade wraps and inlays look great! And your final picture of the finished product is beautiful to my eyes.

To be honest, epoxy is always a challenge for me, and I have been a builder for a long time. Thankfully, I have become better at it, but never what I would call perfect. You have probably already searched and seen all the advice for applying thread epoxy. Everyone has their own take on what works (or is acceptable) for them (which is not to say all advice is good advice for you. (One thing I learned rather late in the game was that the ambient temperature of the build-room played a bigger part than I had valued. No wonder I struggled with my winter time epoxy work in the basement! Ha!)

I have had the exact same experiences and tried the same remedies you have described. Most of the time, I shoot for and get what is reasonable and acceptable to me from years of wrestling with my perfectionism.

I've seen many PICTURES of rods with 'perfect finishes', but held very few in my hands....because the ones I can look at and touch in person usually are not 'perfect.' (Terry Henson showed me a feather in-lay fly rod at an Expo years ago that made me want to worship and kill him at the same time! Ha!)

To answer your questions directly:

Is this Normal? Yes.

Is this an acceptable result? To me, Yes; to your son it seems, Yes; to YOU...?

Keep at it! You are doing very well, IMO!

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 12:07PM

Mark, Daryl...thanks for the kind words and my son will be jovially smug you agree with him haha.

Les, thanks as well. I'm glad that you have trouble with epoxy as well haha. It is my single most stressful part of rod building. I think my favorite stage of building is right after finishing all the wrapping. It's like "this is as clean as this thing will ever be"...and then roll the dice and hit it with the epoxy. I've tried many ways to get good results yes. What I have noticed recently is that i have good luck with the guide wraps. I put the epoxy on the guides and base wrap, let the whole mess sag, wick all the drips off after a couple minutes, start the 180 flipping while watching for the subtle sagging that signals time to turn, then I start fussing with the base wrap and more or less ignore the guide wraps except for chasing a few bubbles with a straw. In the end I end up happy with the guide wraps more or less and frustrated with the base wrap which is about 7 inches long. I watched a video by Bill Falconer sanding down a base wrap and redoing the epoxy and it looked flat I swear...

A closer look at the inlays...this is all size a thread.

Re: Epoxy is hard (for me...)

Posted by:

John Cates

(Moderator) Date: February 21, 2023 12:46PM

When we shot this video it changed my life. I had the same wavy problems up until I learned this technique from Roger Seiders. Check it out:

[ www.youtube.com]

Flex Coat Company

Professional Rod Building Supplies

www.flexcoat.com

Re: Epoxy is hard (for me...)

Posted by:

Michael Tarr

(---) Date: February 21, 2023 12:48PM

This guy A.Sava has one of the best looking finished rods I’ve seen.

[ youtu.be]

Re: Epoxy is hard (for me...)

Posted by:

Lance Schreckenbach

(---.lightspeed.hstntx.sbcglobal.net) Date: February 21, 2023 01:19PM

When we look at anything under a microscope we will see the flaws. Nothing is perfect, only God can do that, we just try to get as close as possible. I hope this comforts you as it has me in the past. I am very anal about anything I do and at some point you just have to step back and let it be. I only use a brush, I have tried other methods and this works best for me. A light thin coat applied with the blank spinning fast, after setting, another coat a little bit thicker turning slower, that will fill in the thread grooves come back after doing all the wraps while it is still soft and even up that coating with little dabs where it needs it looking at the side profile of the area. A contrasting background in your line of site will help. Apply a little heat from a clean burning source (alcohol burner) while turning and let it set with your dryer spinning at about 12 RPM. I have found this to be the best speed. I can usually do most things with two coats. Your wraps look awesome and really so does the epoxy.

Edited 1 time(s). Last edit at 02/21/2023 01:20PM by Lance Schreckenbach.

Re: Epoxy is hard (for me...)

Posted by:

David Sytsma

(---.res.spectrum.com) Date: February 21, 2023 01:56PM

I've had very good success with epoxy, but it took a little trial and error. My method isn't much different from the YouTube video that John Cates provided. Some of my process will not be what others more gifted than me do.

1. Make sure your thread is clean before you start. I use masking or blue painter's tape and pat the wrap to remove any dust or debris.

2. All epoxy finishes have their individual quirks. Choose one you like and stick with it to get a feeling for it's characteristics. Personally I use Flex Coat Lite; two thin coats which allows me to sand or cut out fuzzies, dust, or any perfections noticed after the 1st coat. Sometimes a 3rd coat is needed, but rarely.

3. I always use color preserver on all threads, NOCP or not. Why? Because it seals up the little gaps between the threads which allow air to migrate to the surface after the epoxy has been applied. I've found that it greatly decreases bubbles. Any bubbles that do show up I use a drinking straw and BARELY breathe through it about 4" from the wrap surface and the bubbles quickly pop. I've never had a guide pull out on any rod because the epoxy wasn't allowed to "saturate" the thread.

4. I keep the temperature in my shop at 70-72 degrees all the time, so the epoxy is also at that temperature. I can tolerate a little cooler, but not hotter. This allows the finish to dry slowly and it will self level nearly every time. I also machine mix my epoxy 95% of the time. You can do it with a stir stick in a cup, but follow the directions for mixing time. Pour the mixed finish on some aluminum foil to lengthen the pot life.

5. On saltwater rods I may use a very tiny artist brush to ensure the tunnels are filled, usually after I've looked at the dried first coat, but rarely have to do that. I have a power wrapper, but never apply the finish with the drying motor. I'm reluctant to drop several hundreds of dollars on a high speed finishing unit, so I use the wrapping motor, turn the rheostat all the way off, put a brick on the foot pedal so it stays fully depressed, and carefully increase the rheostat until it's going at least 60rpm. It's not super precise, so you may have to tweak it during the process, but it works for me. I apply the epoxy like it's done in the video. The speed allows you to move that "wave" to the edges and you always get a nice clean line. I also don't put thick coats down; I think it helps create the wavy problem you're having. Be sure to take the brick off the foot pedal when you're done applying the finish; it can get really exciting if you forget and go to wrapping a rod.

6. Once the epoxy is on and apparently bubble free, even if it's a little wavy (you should already be noticing that the epoxy is starting to flatten out) I switch over to the drying motor, shut off the heating duct so there's no air flow to move any dust around, carefully exit the room and stay away for about 6 hours before I do anything else in the shop.

Re: Epoxy is hard (for me...)

Posted by:

david taylor

(---) Date: February 21, 2023 02:11PM

On those long epoxy stretches, I put on a thin coat with DNA, then sand with 300 grit or more paper to even it out, and finish with one or two more coats after that.

Re: Epoxy is hard (for me...)

Posted by:

David Sytsma

(---.res.spectrum.com) Date: February 21, 2023 02:45PM

Bob,

I forgot to compliment you on your thread work. It truly is magnificent; way beyond what I can do.

Dave Sytsma

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 03:44PM

John Cates Wrote:

-------------------------------------------------------

> When we shot this video it changed my life. I had

> the same wavy problems up until I learned this

> technique from Roger Seiders. Check it out:

>

> [ www.youtube.com]

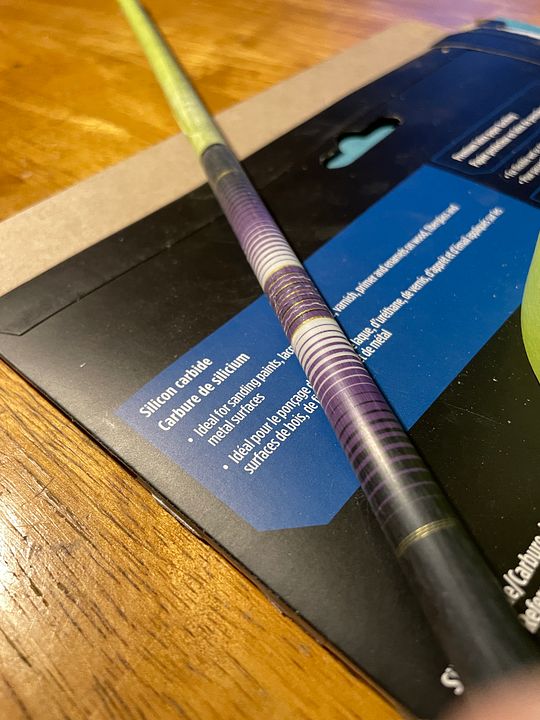

I've watched it a number of times. SO many times actually. Basically started applying at higher speeds because of it. I'll have to watch it a couple more times. Also I like the fellow's manner, kinda fills you with hope. I use a spatula mostly but have been trying out these brushes in 3/16" and 3/8" inch. I tried the 3/8 on this butt wrap but defaulted back to my spatula. I'm going to revisit brushes for sure. I've got a couple 4 oz kits of flex coat lite waiting to try also. am currently using the u40 supreme dura gloss and have been for the last 9 builds or so

[ www.mcmaster.com]

Edited 1 time(s). Last edit at 02/21/2023 03:59PM by Bob Foster.

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 03:52PM

Michael Tarr Wrote:

-------------------------------------------------------

> This guy A.Sava has one of the best looking

> finished rods I’ve seen.

>

> [ youtu.be]

I had seen this as well and watched it a number of times and he makes it look so easy. He really seems to get good results. My goal the last few applications has been to get to bubble free as soon as possible and then stop messing with it. During a recent attempt I had all but stopped messing with it, saw a bubble, then saw a small fish eye / thin spot, panicked, grabbed my spatula and tried some lengthwise strokes and did so too late and the epoxy has started to set up a bit.

So many epoxy adventures. At one point I leaned over a set of grips I was applying epoxy to in order to get a look at this butt wrap. I have a beard that is about 10 inches long and it got caught in the fresh epoxy on the fighting butt and wrapped my beard into the fresh epoxy. This led to such a sense of defeat that I didn't even get overly mad. It took a bit of time and DNA to get it all sorted out.

Live and learn I suppose

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 03:53PM

david taylor Wrote:

-------------------------------------------------------

> On those long epoxy stretches, I put on a thin

> coat with DNA, then sand with 300 grit or more

> paper to even it out, and finish with one or two

> more coats after that.

I've been tempted to thin my mix but haven't found the courage yet haha

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 03:56PM

David Sytsma Wrote:

-------------------------------------------------------

> Bob,

>

> I forgot to compliment you on your thread work. It

> truly is magnificent; way beyond what I can do.

>

> Dave Sytsma

That's very kind and thanks for the advice. My shop usually runs 75 to 79 degrees. I usually warm the epoxy up some setting the bottles on our pellet stove until they feel warm to my hand but never hot.

I may try one more time to sand it and reapply.....or I may not haha. Only the wind knows for sure

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 04:03PM

Lance Schreckenbach Wrote:

-------------------------------------------------------

> When we look at anything under a microscope we

> will see the flaws. Nothing is perfect, only God

> can do that, we just try to get as close as

> possible. I hope this comforts you as it has me in

> the past. I am very anal about anything I do and

> at some point you just have to step back and let

> it be. I only use a brush, I have tried other

> methods and this works best for me. A light thin

> coat applied with the blank spinning fast, after

> setting, another coat a little bit thicker turning

> slower, that will fill in the thread grooves come

> back after doing all the wraps while it is still

> soft and even up that coating with little dabs

> where it needs it looking at the side profile of

> the area. A contrasting background in your line of

> site will help. Apply a little heat from a clean

> burning source (alcohol burner) while turning and

> let it set with your dryer spinning at about 12

> RPM. I have found this to be the best speed. I can

> usually do most things with two coats. Your wraps

> look awesome and really so does the epoxy.

"When we look at anything under a microscope we

will see the flaws" ....a great life lesson here.

I've never heard a reference to using the side profile to actively doctor the epoxy but now that you say it and I watch the asava guy video this may be another trick in the bag to try out....thanks for that.

Re: Epoxy is hard (for me...)

Posted by:

Tom Kirkman

(Moderator) Date: February 21, 2023 04:07PM

It is not only possible, but easy, to get epoxy to level to the point that it in fact looks like a glossy sheet of glass over your wraps. Two things matter most - put on neither too little nor too much and try not to bother the epoxy once you have applied it. Let it do what it was formulated to do.

..............

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 04:11PM

Les Cline Wrote:

-------------------------------------------------------

> Bob,

>

> First off, that is some very detailed threadwork!

> Your fade wraps and inlays look great! And your

> final picture of the finished product is beautiful

> to my eyes.

>

> To be honest, epoxy is always a challenge for me,

> and I have been a builder for a long time.

> Thankfully, I have become better at it, but never

> what I would call perfect. You have probably

> already searched and seen all the advice for

> applying thread epoxy. Everyone has their own take

> on what works (or is acceptable) for them (which

> is not to say all advice is good advice for you.

> (One thing I learned rather late in the game was

> that the ambient temperature of the build-room

> played a bigger part than I had valued. No wonder

> I struggled with my winter time epoxy work in the

> basement! Ha!)

>

> I have had the exact same experiences and tried

> the same remedies you have described. Most of the

> time, I shoot for and get what is reasonable and

> acceptable to me from years of wrestling with my

> perfectionism.

>

> I've seen many PICTURES of rods with 'perfect

> finishes', but held very few in my

> hands....because the ones I can look at and touch

> in person usually are not 'perfect.' (Terry Henson

> showed me a feather in-lay fly rod at an Expo

> years ago that made me want to worship and kill

> him at the same time! Ha!)

>

> To answer your questions directly:

> Is this Normal? Yes.

> Is this an acceptable result? To me, Yes; to your

> son it seems, Yes; to YOU...?

>

> Keep at it! You are doing very well, IMO!

I googled Terry Henson.....SUCH nice work!

Re: Epoxy is hard (for me...)

Posted by:

Donald La Mar

(---) Date: February 21, 2023 05:22PM

The problem with apply, wait for drips, wick the drips, flip, wait and repeat is that while you flip and wait the epoxy is curing and the wait time therefore gets longer and longer to detect the excess epoxy.

The good news is you can speed things along by using a bit of heat to loosen the applied epoxy causing it to drip or sag more quickly. Mind you heat is a hard task master - too much heat and you'll cook the epoxy and make a royal mess. And for goodness sake don't use heat until you have practiced, practiced, practiced on scrap blanks and consistently achieved success.

You might find this Doc Ski video entertaining and maybe instructive. [ www.youtube.com]

Edited 1 time(s). Last edit at 02/21/2023 05:23PM by Donald La Mar.

Re: Epoxy is hard (for me...)

Posted by:

Bob Foster

(205.234.62.---) Date: February 21, 2023 06:40PM

The video was entertaining and instructive. From what I saw there what I am doing is at least on par with what the gentleman in the vid is putting out but I would love to see the epoxy flatter. I would go crazy with that many bubbles in the epoxy but as the fellow says, he does what works for him. I've been at this for a couple years now and this is rod #16....still finding what works for me I guess. I wonder what life is like on the flat upper portion of the learning curve.....

Sorry, only registered users may post in this forum.

|