Blank Variance - how much is too much?

Posted by:

Aleks Maslov

(Moderator) Date: January 07, 2024 01:59PM

Dear Rod Builders,

There has been a few posts about blank variances, and while I cannot address those of different manufacturers, I can address those related to NFC.

I had an email exchange with a customer/participant of this forum, and our thread is below. If they wish, they can chime in, but below is an excerpt from our discussion, with some more info added:

I hope that it serves to educate.

------------------------------------------------------------------

Regarding the butt / tip diameters of blanks :

Carbon fiber in pre-preg form from the manufacturer has two variables - fiber content and resin content, so when receiving a roll of material the specs always call out for +/- 5%,

This means that in a given 100 meter roll of material, you may have up to 5% variance on each of those variables - if the specs call for a 30% resin content and 100 grams of fiber per square meter (gsm) it may come back with 105 grams on one batch, and 35% resin, and 95 grams for another batch with 25% resin content.

Or, it can be 103 grams and 35% resin content - etc - you get the picture.

That pre-preg gets wrapped around a mandrel and if two weeks ago a batch of material was received with a low resin / low fiber content and this week a higher resin higher content - the material is slightly thicker.

We have a "retain" (which is like a meter stick in the vault in Paris) which is the "master blank" it has a specific weight, butt and tip diameter and flex.

One thing that NFC does differently (and always has) is we never grind our blanks to a specific diameter - we just sand off the excess resin, and those blanks that are sanded, finish by hand sanding or hand polishing them. The reason why we do this, is because we don't incorporate sacrificial layers of material into our blanks - (many do for the resin / fiber variance reason I describe above) and then send the blank through a grinding machine to achieve the "posted tip and butt diameter"

We don't put our blanks through a grinding machine (which may have a tighter tolerance, because we don't want to take the chance on sanding into the actual fiber. In fact, if the blank is "always consistent" you can be sure that this is obtained by grinding the blank - and in our opinion, this is never good.

What we do instead is measure the following:

1) A 12 inch square gets cut out of every roll of material before it gets cut into patterns. This 12 inch piece is weighed against the "retain" piece of material. If the variance of within the tolerance described above - the roll of material is approved for production / if not, it gets rejected to the manufacturer.

2) As parts are made (we try to run based on Mandrel availability - but usually in batches of 50 or so) and blanks come out of production - 10% of the 50, or 5 blanks will get put on a flex board against the original retain, and if the flex passes (within an inch of the original curve) the blanks get sent further for QC, etc.

If the blanks fail, the entire batch gets flexed, and those that meet the flex requirement pass. Can you have a batch of blanks that pass QC, but at the same time have a blank in the bunch that is out of spec? Yes, a wrong mandrel can get mixed into the batch of 100, and then missed. (This has made for some interesting searches and discoveries of trying to recreate a blank, or an accidental blank design!)

Our "guiding light" is the same/very similar flex/action of the blank against the retain - this is what dictates what technique the blank was designed for, etc. The tolerance is smaller for lighter blanks, half inch, and greater for blanks that are more powerful, 3/4 of an inch, etc. (The key is that they cant cross over into the "next power rating" of the same range)

The diameter will fall within a range, the two blanks you received are the same due to being made out of the same batch of material, or different batches with the same resin / fiber content, not because they are the "wrong blanks" - they passed the flex test.

The reason why we choose the latter approach, is that when you are grinding a blank to a specified OD, blanks are never perfectly round - it's a layer of material that lays on top of another - it will have a high side and a low side, and by grinding - at some point you will grind into the low side, up at the middle of the blank, or higher, and on some unlucky cast - the blank will fail.

We will always take the blanks back - and can try to accommodate the stated diameter, but no guarantees - Torays / Hexcels tolerances are what they are.

Aleks

Edited 2 time(s). Last edit at 01/07/2024 02:46PM by Aleks Maslov.

Re: Blank Variance - how much is too much?

Posted by:

Tim Scott

(---) Date: January 07, 2024 02:33PM

Ordering 7 ft and one is 1/2 under, one on point, one 2” long all same model. Tip sizes were identical. Just as any FYI. Building for family so all performed to the purpose. My weights have all been close enough +- 5%.

Just a kudos for bringing out the PSI fly blanks in lower wts. Very nice actions. I prefer a bit more moderate fly blank these days.

Re: Blank Variance - how much is too much?

Posted by:

Al purvis

(---) Date: January 07, 2024 02:35PM

Aleks Maslov Wrote:

-------------------------------------------------------

> Dear Rod Builders,

>

> There has been a few posts about blank variances,

> and while I cannot address those of different

> manufacturers, I can address those related to

> NFC.

>

> I had an email exchange with a

> customer/participant of this forum, and our thread

> is below. If they wish, they can chime in, but

> below is an excerpt from our discussion, with some

> more info added:

>

> I hope that it serves to educate.

>

> --------------------------------------------------

> ----------------

>

> Regarding the butt / tip diameters of blanks :

>

> Carbon fiber in pre-preg form from the

> manufacturer has two variables - fiber content and

> resin content, so when receiving a roll of

> material the specs always call out for +/- 5%,

>

> This means that in a given 100 meter roll of

> material, you may have up to 5% variance on each

> of those variables - if the specs call for a 30%

> resin content and 100 grams of fiber per square

> meter (gsm) it may come back with 105 grams on one

> batch, and 35% resin, and 95 grams for another

> batch with 25% resin content.

>

> Or, it can be 103 grams and 35% resin content -

> etc - you get the picture.

>

> That pre-preg gets wrapped around a mandrel and if

> two weeks ago a batch of material was received

> with a low resin / low fiber content and this week

> a higher resin higher content - the material is

> slightly thicker.

>

> We have a "retain" (which is like a meter stick in

> the vault in Paris) which is the "master blank" it

> has a specific weight, butt and tip diameter and

> flex.

>

> One thing that NFC does differently (and always

> has) is we never grind our blanks to a specific

> diameter - we just sand off the excess resin, and

> those blanks that are sanded, finish by hand

> sanding or hand polishing them. The reason why we

> do this, is because we don't incorporate

> sacrificial layers of material into our blanks -

> (many do for the resin / fiber variance reason I

> describe above) and then send the blank through a

> grinding machine to achieve the "posted tip and

> butt diameter"

>

> We don't put our blanks through a grinding machine

> (which may have a tighter tolerance, because we

> don't want to take the chance on sanding into the

> actual fiber. In fact, if the blank is "always

> consistent" you can be sure that this is obtained

> by grinding the blank - and in our opinion, this

> is never good.

>

> What we do instead is measure the following:

>

> 1) A 12 inch square gets cut out of every roll of

> material before it gets cut into patterns. This 12

> inch piece is weighed against the "retain" piece

> of material. If the variance of within the

> tolerance described above - the roll of material

> is approved for production / if not, it gets

> rejected to the manufacturer.

>

> 2) As parts are made (we try to run based on

> Mandrel availability - but usually in batches of

> 50 or so) and blanks come out of production - 10%

> of the 50, or 5 blanks will get put on a flex

> board against the original retain, and if the flex

> passes (within an inch of the original curve) the

> blanks get sent further for QC, etc.

>

> If the blanks fail, the entire batch gets flexed,

> and those that meet the flex requirement pass. Can

> you have a batch of blanks that pass QC, but at

> the same time have a blank in the bunch that is

> out of spec? Yes, a wrong mandrel can get mixed

> into the batch of 100, and then missed. (This has

> made for some interesting searches and discoveries

> of trying to recreate a blank, or an accidental

> blank design!)

>

> Our "guiding light" is the same/very similar

> flex/action of the blank against the retain - this

> is what dictates what technique the blank was

> designed for, etc. Does this mean that our people

> are perfect, and that

>

> The diameter will fall within a range, the two

> blanks you received are the same due to being made

> out of the same batch of material, or different

> batches with the same resin / fiber content, not

> because they are the "wrong blanks" - they passed

> the flex test.

>

> The reason why we choose the latter approach, is

> that when you are grinding a blank to a specified

> OD, blanks are never perfectly round - it's a

> layer of material that lays on top of another - it

> will have a high side and a low side, and by

> grinding - at some point you will grind into the

> low side, up at the middle of the blank, or

> higher, and on some unlucky cast - the blank will

> fail.

>

> We will always take the blanks back - and can try

> to accommodate the stated diameter, but no

> guarantees - Torays / Hexcels tolerances are what

> they are.

>

> Aleks

Good stuff Aleks! Thanks for sharing the info.

On an unrelated note, a lot of the iconoglass rods say out of stock on your website. Some have a live inventory. Can we still order those and wait for them to be back ordered or how does that work? I understand you may not keep a stock of every blank you have listed but I hadn’t noticed other blanks stating “out of stock.”

Re: Blank Variance - how much is too much?

Posted by:

Aleks Maslov

(Moderator) Date: January 07, 2024 02:47PM

Al,

Yep - you can still order, (if it says "read more" send Kelsey an email, that happens when she has some amount already on backorder). The IG blanks (all) should be back in stock by end of Jan - they sell out during the BFCM periods.

Aleks

Re: Blank Variance - how much is too much?

Posted by:

Al purvis

(---) Date: January 07, 2024 02:54PM

Thanks! It was more of a for future reference question, I noticed that last night when I placed my order. Gonna need an 8wt glass in the near future!

Re: Blank Variance - how much is too much?

Posted by:

Norman Miller

(Moderator) Date: January 07, 2024 03:11PM

Al, you will love the NFC IG fly rods. I’ve made both a 5 wgt and 8 wgt. They have a very unique but pleasant feel about them and they cast exceptionally well. I’m sure I’ll be ordering more.

Norm

Re: Blank Variance - how much is too much?

Posted by:

Al purvis

(---) Date: January 07, 2024 03:27PM

I’m excited norm! I built a 4wt for myself a while back and it is an absolute canon!

Re: Blank Variance - how much is too much?

Posted by:

david taylor

(---) Date: January 07, 2024 05:59PM

Well delineated, Aleks, thanks. Much interesting detail.

Many tend to forget a carbon fiber tube produced from being wrapped on a mandrel is never going to be uniformly round.

I suppose at one's own potential expense one could sand down your blanks, or at least take down the ribs a fair degree. I could not be bothered and, as you indicated, and especially via hand sanding and not a precise machine, one could certainly go a hair too far and weaken the narrowest wall area of a blank.

Ribbed or unsanded blanks pose a slight increase in wrapping difficulty, but it is minor, especially when one gets the hang of it.

Re: Blank Variance - how much is too much?

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 07, 2024 06:54PM

I'm the customer / participant of this forum that Aleks mentions at the beginning of this thread. I was questioning why the butt diameter of two of the blanks I received were quite a bit different than the dimensions listed on the NFC web site. What he posted is a copy and paste from his reply to my e mail. I appreciated him taking the time to give me such a detailed explanation. Everything he said makes sense. I for one was not aware that other manufacturers may grind their blanks to match specific dimensions.

And I assume that not grinding the blanks and not incorporating sacrificial layers into their blanks, helps keep costs down to us, the consumer. I can't remember the last time that the X ray blanks haven't been on some kind of sale. $75 for the OG finish X ray and $95 for the mirror finish version is an outstanding value for a blank of that caliber.

I'm curious as to what kind of load is used when checking blanks on the flex board, to see if they either pass of fail? Is the load used to test the flex of a blank the same load that is pictured deflecting the blank on that blank's page on the web site?

For instance, an MB733X ray blank, which is the blank in question that prompted the e mails Aleks and I exchanged, is shown being deflected by 12 oz of weight. Is that the amount of weight used to check the blanks flex? Is the load used for checking the flex of a blank, based on the blanks lure weight ratings? The amount of weight it would take to fully load a blank per CCS standards?

Or is there a range of weight that can be used to flex test a blank, or is it the specific amount of weight used when determining the flex profile of the retain, master blank?

Re: Blank Variance - how much is too much?

Posted by:

Russell Brunt

(---) Date: January 07, 2024 08:04PM

Aleks, I think a +/-, or range, from a published CCS number, would be helpful. It does seem there have been occasions in the past where someone may have ended up with something different based on CCS numbers they have posted.

Sometimes that works out for the best though (and I dare say David might be a case when I suspected he got a SJ 736).

Russ in Hollywood, FL.

Re: Blank Variance - how much is too much?

Posted by:

Les Cline

(---) Date: January 08, 2024 11:28AM

Aleks,

Thank you for the information about blank production! The peek behind the curtain is greatly appreciated.

And thank you for taking the time and attention to getting into the weeds with the details in response to David Baylor. On the forum, there is a group of builders that have a high level of trust with me because they are courteous, curious, and competent. When one member of that group shares an experience or bit of knowledge, it gets my attention. They ask the questions I didn't know to ask yet. They know things I don't know yet. I take what they share to heart. And in a proxy kind of way, how you treat them is how you will treat me. IMO, this is the kind of partnership the forum is all about.

Another case in point: My decades-long fishing buddy never built his own rods. A couple of years ago, he wanted to get into it. Now, he texts me about the latest deals from NFC and has purchased at least six blanks and various grips so far (as well as rod-wrapping tools, thread, epoxy, etc. which expands the sales impact). I shared with him what you said about blank production and blank variables, and he was fascinated. Trust is contagious. Your willingness to share information builds trust.

I am CCS testing all the blanks I buy (and so is my buddy) and paying more attention to the details....and where that rod fits on the continuum of power and action with what is already in the rod locker. Information is King.

Sine a light on it.

Re: Blank Variance - how much is too much?

Posted by:

Aleks Maslov

(Moderator) Date: January 09, 2024 09:34PM

Thank you ALL for your kind words.

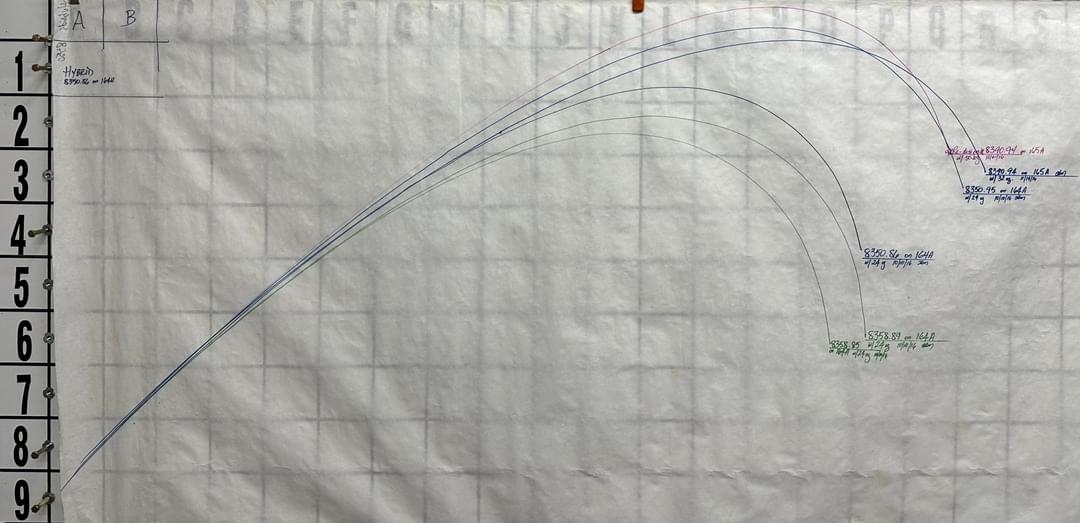

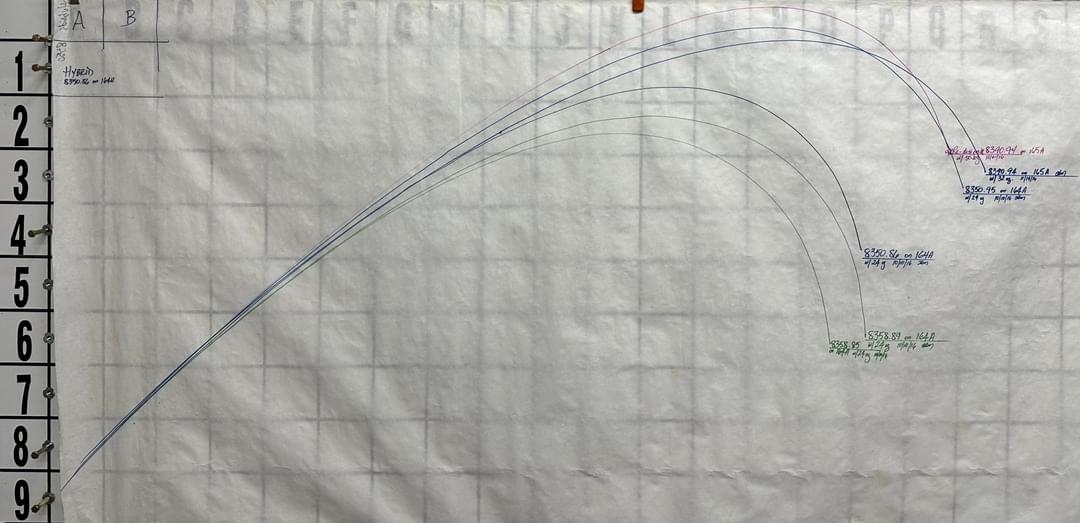

A picture is worth 1,000 words - so here’s a picture:

David - to answer your question is that when a blank gets designed, and approved for production, it gets a “master curve” which is derived from the retain.

The 10% of blanks that get flex tested against the retain, get put on a production flex board when the pattern is being ran.

The picture represents a hybrid series, so when that pattern number gets ran, it will get put in the board against a retain blanks curve. (This way, we have both, the master sheet, and the retain, from which we get the curve on the sheet)

The sheet calls out for the weight that the original was deflected against.

(This also serves as a double security - if the retain blank gets lost, we have the master curve, or if the Tyvek type sheet gets damaged, it can get re-created)

If production is running a blank - let’s say the MB 705, the same sheet will have the curves for MB 700, 701, 702, 703, 704, 705, 706 etc on it.

In general, the pattern will pass a flex test if it does not go into the “power” of the blank next to it. (Some of the powers are a half inch apart, 3/4 etc.)

Aleks

Re: Blank Variance - how much is too much?

Posted by:

Aleks Maslov

(Moderator) Date: January 09, 2024 09:35PM

Adding a comment so that the one posted from the app shows a new post. (You have my vote for this fix as the next update!)

Aleks

Re: Blank Variance - how much is too much?

Posted by:

Les Cline

(---) Date: January 10, 2024 10:29AM

How sweet is that!

Thanks again, Aleks! This further enhances my understanding of 'variables' between rods of the same model. Rods are not like a pot of stew that you can add a little more salt to after it is made to adjust the taste.

What happens to a 704 that looks like a 703 or 705 when put on the board? Do they get scrapped, recycled or re-purposed in some way? Same question for the trimmed pieces.

In general, how do you determine what power number a rod receives?

I am a fan of the deflection charts you show with each blank model. At the very least, it gives me a quick read on the action of that particular blank - and the weight listed to deflect it hints at its power. My newbie buddy bought what he called "The Ultimate Crappie Blank" and pointed me to the NFC chart.

Any updates on the Pro Shop opening?

Re: Blank Variance - how much is too much?

Posted by:

Robert Henry

(57.140.28.---) Date: January 10, 2024 11:11AM

This thread should get a sticky.

This topic comes up quite often and the information provided by Aleks is great, especially as a newer builder. Thanks for the transparency and insight backed by actual data and process on how NFC does business. No doubt this has earned NFC even more respect.

Re: Blank Variance - how much is too much?

Posted by:

Harry Sandoval

(---.hsd1.ut.comcast.net) Date: January 10, 2024 05:11PM

I hope this isn't a stupid question, but how much variance in straightness is acceptable?

Would this be best measured in deviation from a straight edge in millimeters or is their a better way?

I recently had a tip section that looked too crooked to use, but I placed guides on the straightest axis with O-rings and couldn't really see the bends; so I wrapped it and enjoy how the rod fishes...

Just curious when I should send a blank back because it is too crooked?

Re: Blank Variance - how much is too much?

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 10, 2024 06:49PM

Aleks, I really appreciate you taking the time to post this kind of information. Probably not many in your position would go to these lengths. I suspected that the specific amount of weight used to defect the retain, was also used to test the subsequent built blanks, but wasn't positive. What you posted and depicted, clears up any question I, or others might have had. Again, I really appreciate your openness, and willingness to share.

I go to the Rodbuilding.org CCS data base quite often when I'm looking to purchase a blank, and when I've seen CCS numbers vary as much as I have, I've often wondered how they can be so different from one another, Your saying that in general, the pattern will pass a flex test if it does not go into the “power” of the blank next to it, helps understand it better.

If I am understanding this correctly, using the MB 704 as an example. It can either almost be an MB 703, or almost an MB 705? That certainly explains why, aside from possible testing errors when CCSing a blank, the variations in CCS numbers I'm seeing in the Rodbuilding. org data base. Makes sense ..... now. lol

Once again, thank you for caring enough to take the time to answer my questions, and to bring this to the board. It's good stuff that as definitely answered more than a few of my questions.

Re: Blank Variance - how much is too much?

Posted by:

Aleks Maslov

(Moderator) Date: January 13, 2024 02:38PM

Thank you David, Les, all.

@ David - correct, if a pattern does not go into the next blank powers curve, it will pass the flex test.

Very rarely you will have a 703 becoming two powers heavier - this means that the fiber and the resin in the material were way out of spec, OR a wrong mandrel got mixed into the batch. In both cases, the blank would be scrapped, because even if the flex measured out to a 705, there is not enough material wraps around the mandrel to classify it for a heavier power. (I think there was a question on this earlier)

@ Harry - you are going to get A LOT of opinions on this. We will build on a curved blank, as long as the curve does not go in the opposite way of the spine.

Aleks

Re: Blank Variance - how much is too much?

Posted by:

Eric Gagnon

(---.public.eastlink.ca) Date: January 14, 2024 10:35AM

Hi people. A more basic question here. To flex test a blank do you glue a tip top on temporarily or have some other method of pulling on the end of the blank

Re: Blank Variance - how much is too much?

Posted by:

Tom Kirkman

(Moderator) Date: January 14, 2024 11:26AM

Backlash Tools used to make some slip-on devices for this purpose but I don't believe they are available any longer. In the interim simply glueing on a tiptop with hot melt easily suffices. Do it properly and you're not likely to have the top come off under direct load.

...........

Sorry, only registered users may post in this forum.

|