Re: wrap epoxy feels rough

Posted by:

roger wilson

(---) Date: January 08, 2023 11:32AM

Ed,

For myself, I do the pull through similar to yours. However, with a long pull thread so that you can put a lot of tension on the thread, I pull it about as tight as i can pull it - and then, while holding lots of tension on the thread, I use a pair of very fine tipped Dr. Slick's fly tying scissors to trim the thread tight to the wraps. With the nylon thread stretched very tight - the cutting of the tag end will allow the stretch to come back out of the thread and the tag end will disappear back under the wraps.

Choose, the scissor, or scissor's of your choice:

[ www.drslick.com]

Be safe

Re: wrap epoxy feels rough

Posted by:

Norman Miller

(Moderator) Date: January 08, 2023 11:51AM

You certainly did not cut the tag short enough. Pull the tie off loop right up to the edge of the wrap so it snugs up tight to the wrap. Then cut the thread tag as close as possible to the loop. Now when you pull the loop out the tag end be under the wrap with no nub sticking up as shown in your photo. Close but no cigar! Try again. Once you get it right you will never do it otherwise. As I mention previously I use very sharp fine tip scissors, similar to the Dr Slick spring scissors. I like the curved type. The spring type is very easy to use, no finger loops to slow things down. Pick up, snip and you’re done. Plus you don’t have to keep buying fresh razor or scalpel blades. Been using the same pair for years on hundreds of rods, and they are still sharp.

[ www.amazon.com]

Norm

Re: wrap epoxy feels rough

Posted by:

Kevin Fiant

(---) Date: January 08, 2023 03:11PM

El - thus far I have been using the method Tom Kirkman suggest in the video linked below. Has worked pretty well for me thus far. I haven't tried the "longer pull thru" method yet but may give it a go also and see which one I find easier to work with. Don't get me wrong, all mine haven't been perfect and in a couple cases had to redo but I chalk that up to part of the learning process.

[ youtu.be]

Re: wrap epoxy feels rough

Posted by:

Lynn Behler

(---.44.66.72.res-cmts.leh.ptd.net) Date: January 08, 2023 06:36PM

Learn to do it as Norm said. You will not go back. The sooner you put the pull loop in the wrap the more wiggle room you have with cutting the wrap thread so close to to the loop once it's tightened up. Why pull the tag up through your beautiful wrap and then cut it with a razor blade if there's no need for it in the first place?

Re: wrap epoxy feels rough

Posted by:

Mark Brassett

(---) Date: January 08, 2023 07:20PM

My rod building life changed for the better the day I started putting the loop in early. I solved the occasional tie off end fuzzies by wetting my finger a little and "pasting" the cut end to the blank before wrapping over it.

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(50.233.0.---) Date: January 10, 2023 11:57AM

I'm taking it all in, gonna compare both ways and invest in something Dr. Slick.

I did some more wraps last night and all had the same result tugging tight with pull through and then cutting close, but maybe I just need to find a way to cut closer. I was thinking after maybe its the angle I was pulling through, should it be 45 up and slightly in the direction of the wrap? I had been going for just 45 degrees parallel to the blank. Maybe the scissors will do better than a razor blade.

Re: wrap epoxy feels rough

Posted by:

Norman Miller

(Moderator) Date: January 10, 2023 04:37PM

Maybe you just need to insert the tie off loop earlier. If you pull your loop out at 45 degrees you may be pulling more thread under the wrap then needed. Just pull the loop straight back at 90 degrees.

Norm

Edited 1 time(s). Last edit at 01/10/2023 04:41PM by Norman Miller.

Re: wrap epoxy feels rough

Posted by:

Mark Brassett

(---) Date: January 10, 2023 07:01PM

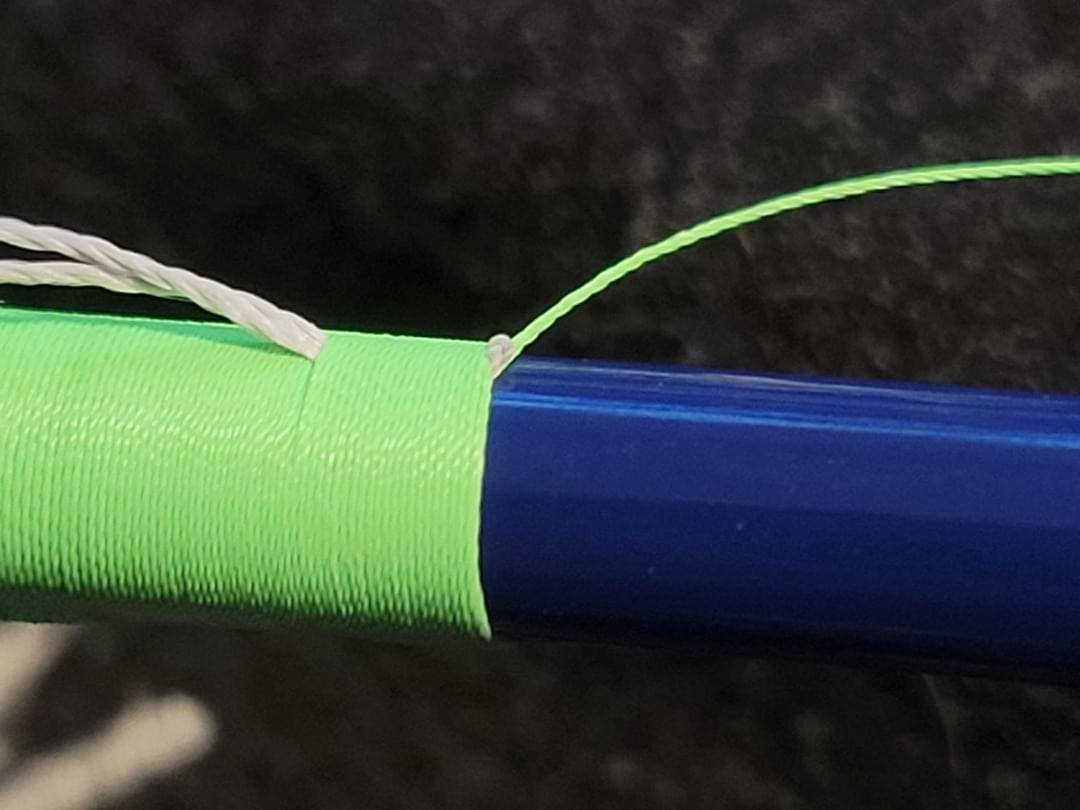

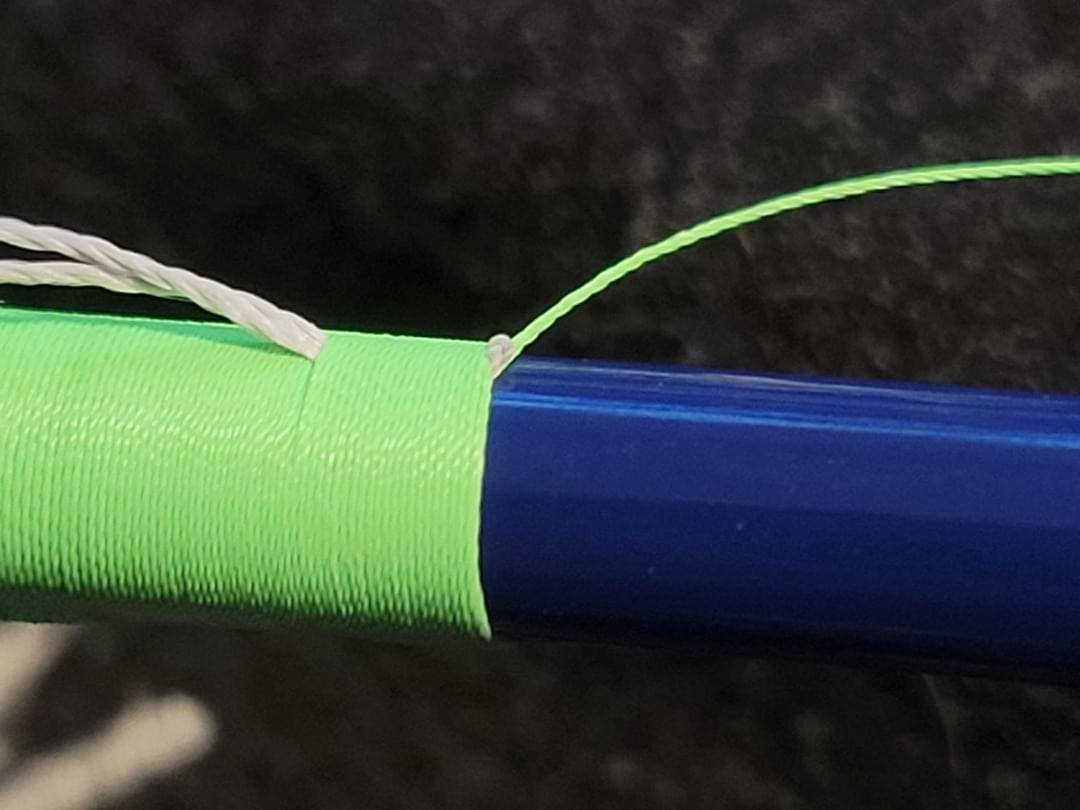

Looking at your 2nd photo, Insert the loop 10 wraps earlier and that problem will disappear.

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(71.184.77.---) Date: January 10, 2023 11:51PM

This is my latest wrap - done by hand and tighter than others. Next time I will put the pull through in even earlier - but another issue popped up. The pull through loop twists at rest. I put my wrapping thread through the loop and then my pull through loop twists further and nubs at the last wrap when pulled tight.

I'm using size d thread as pull through. Switch to A?

Edited 1 time(s). Last edit at 01/10/2023 11:53PM by El Bolinger.

Re: wrap epoxy feels rough

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 11, 2023 06:31AM

Are you worried that your pull through thread may break because you have to pull that small nub under the wrap? If so, my guess is you have some braided fishing line laying around? Just use the braid instead of thread for your pull through.

I use old yellow 65# braid that I tied in a loop and slid a plastic bead on, as my pull through line. The bead and the line being yellow make it easy to identify on the wrapping table, and I have zero worries about it breaking when pulling a tag end through. Yes it bunches up a bit when it gets close to going under the wrap, but if you keep tension on your tag end while holding it close to the rod blank, it helps the pull through start under the wrap.

I use 65# braid because that's what I have on hand. If I had 15 or 20# braid I would go with that as its' smaller diameter would make it easier to pull through.

Edit for addition: Make sure the braid you use is old and well used, Some of the braids today have waxy substances on them, so if you use new line, it may contaminate your wrap. The stuff I use had been used for a good couple of years before I started using it as pull through loop material.

I also have it on the reel I use when doing my static load guide placement. That big thick yellow line makes it really easy to see the line's path.

Edited 1 time(s). Last edit at 01/11/2023 10:08AM by David Baylor.

Re: wrap epoxy feels rough

Posted by:

Norman Miller

(Moderator) Date: January 11, 2023 11:24AM

I use left over or used yellow 15 or 20 lb braid for my tie off loops. Tie a surgeon’s knot in the end to make a loop and you are ready to go. I tie up a bunch of them at one time, in case I drop them on the floor or misplace them. I don’t use a bead, it just seems to get in the way.

Norm

Re: wrap epoxy feels rough

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 11, 2023 04:04PM

Norman, I hear ya on the bead getting in the way. If I don't watch my placement, the beaded end can get caught up the last few finishing wraps. I usually end up using words I shouldn't use in public when that happens. lol

I've just never gotten around to making another one.

Re: wrap epoxy feels rough

Posted by:

Norman Miller

(Moderator) Date: January 11, 2023 04:37PM

I just make a bunch of tie off loops and keep several in my work area. If one falls on the floor or in the trash can, or I misplace it, I just grap another one There are times when I’ll use two tie off loops when doing certain types of trim wraps. I consider them as disposable.

Norm

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(---.bstnma.fios.verizon.net) Date: January 12, 2023 10:31PM

@DAVID I'm not worried about breaking, I just noticed it and was wondering if it could be adding to the issue.

But I practiced with some size a thread and it seemed better, but I'll give some 10# braid a go too.

Building rods in MA, Building the community around the world

Sorry, only registered users may post in this forum.

|