wrap epoxy feels rough

Posted by:

El Bolinger

(---.bstnma.fios.verizon.net) Date: December 30, 2022 01:43PM

The wrap epoxy feels bumpy in some spots. I'm assuming it's stray strands poking up. Is it that? Would a second coat help?

How do you get perfectly flat smooth epoxied wraps?

Re: wrap epoxy feels rough

Posted by:

Tom Kirkman

(Moderator) Date: December 30, 2022 02:07PM

Your thread may be fuzzed.Check your tensioning hardware. A second is unlikely to help by much. If the fuzzies are long enough, they'll simply protrude through the second coat as well. Shave, snip and/0r sand it flat.

To get perfectly flat, smooth epoxied wraps, put the epoxy on the wraps and leave it alone. Let it do what it was formulated to do.

.......

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(---) Date: December 30, 2022 03:26PM

I figured it was fuzz, does too much tension cause fuzz? Does the cutting tool make a difference, razor vs snips, vs dull/sharp scissors?

Re: wrap epoxy feels rough

Posted by:

Tom Kirkman

(Moderator) Date: December 30, 2022 04:13PM

Tension isn't likely to cause fuzz. Whatever your thread is running through is the more likely culprit. The cutting tool makes a difference in terms of the cleanest cut, but it won't cause fuzzies along the thread. Whatever you use, make it something very sharp.

........

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(---.bstnma.fios.verizon.net) Date: December 30, 2022 09:46PM

I'm just running it through the metal loop that came with the Batson rod wrapper.

What about avoiding thread flare after a tie off cut?

Re: wrap epoxy feels rough

Posted by:

Mark Talmo

(---) Date: December 30, 2022 11:04PM

El,

Tom’s comments are good indeed.

You mentioned “What about avoiding thread flare after a tie off cut?” That leads me to believe that you are pulling the final thread tag all the way through and out somewhere in the middle of the wrap, then trying to snip it off so the end does not show. If so, consider an almost fool-proof tie off method instead. Insert your pull-through loop early, let’s say 10 rotations (more is even better) before the end of the wrap. Cut the tag, insert it through the pull-through, and pull the loop just until the tag is firmly against the wrap to hold it in place (actually, pulling the tag until it is under the first {last} rotation of the wrap is good insurance). Cut the tag reasonably close to the edge of the wrap and pull the pull-through loop out; the end of the tag will remain hidden / concealed somewhere under the main wrap without needing to be trimmed again. I wouldn’t think of tying-off a wrap any other way; precise, perfect and no protruding nubs.

Mark Talmo

FISHING IS NOT AN ESCAPE FROM LIFE BUT RATHER A DEEPER IMMERSION INTO IT!!! BUILDING YOUR OWN SIMPLY ENHANCES THE EXPERIENCE.

Re: wrap epoxy feels rough

Posted by:

roger wilson

(---) Date: December 31, 2022 12:12PM

Just a couple of questions.

There have been different wrappers sold by Batson over the years.

To be sure, what device is used to maintain tension on the thread?

Are you using the pair of disks with a spring on one side and a nut to regulate the tension of the spring to adjust the tension of the thread that is running through the disks?

Or, do you have a tension device that puts tension on the thread spool which then maintains tension on the thread as it leaves the spool/

In the case of tension method number 1. Disassemble the nut, spring and tension disks. Then, run your finger nail over the surface of each disk to insure that there are 0 defects of any residual thing of anything that might be sticking up to possibly abrade the thread. Normally with the finish on these disks there are 0 defects. But, if you feel even the tiniest piece of anything that could be thought to be rough - polish it off with polishing compound. Repeat for the 2nd disk, and then reassemble. Often, just lightly dragging a Kleenex off the surface will uncover any irregularities. Normally this is never a problem.

If you have a wrapper that puts tension on the thread spool, be sure that your washers are smooth and that the tension of the thread coming off the spool is perfectly smooth.

Then, for any guides, or loops that the thread is routed through - after leaving the tension device needs to be absolutely free of defects. In this case, use the same method that is used to check for a chipped or defective guide. Take a cotton que tip or cotton swab and run it around each side and through the enter of the guide or thread loop to insure that there is nothing rough that may affect the thread. If you do find a defect with the guide or guides that direct the thread after the tension device before getting to the rod, I would suggest that you remove that guide or loop and replace it with a conventional rod guide with a ceramic, or other liner to insure that you have a perfectly smooth guide loop to direct the thread. In this case, I just take a single foot guide of an appropriate size and press it into the hole that the original loop was placed.

Finally one has to ask the question. Do you have a spool of bad thread. Do you have a spool of thread that has inherent fuzzies?

To check for this, take the spool of thread that was part of your problem, and then using very bright light and magnification, grab the spool of thread in one hand and then pull off about a foot of line. Then, while holding the spool of thread in one hand, and putting about as much tension as you can, on the thread - examine the taunt thread under very bright lights and magnification to check for fuzzies. By that, I mean that if you just check a thread under very little tension, and with bright lights and magnification - you will normally see a very smooth uniform thread. However, as you stretch the thread more and more, you may notice that suddenly, you are seeing little hairs pop off the surface of the thread and become the infamous "Fuzzies" Essentially microfibers are coming apart from the thread and are left in an extended position even after the tension is relaxed. i.e. you have a spool of Fuzzy thread.

Fortunately, this is a very rare occurrence in the thread world. But, if you ever do run across a spool of fuzzy causing thread - there is one simple solution. Take that spool of thread and stuff it deeply into a garbage container and insure that the garbage is disposed of properly.

Over the years, handling many many spools of thread, I am fortunate, in that I have only encountered two spools of fuzzy causing thread, which were quickly cast out of the rod shop.

The bad part of this situation, is that often, the fuzzies doe not show up, until one coating of thread is placed in the thread. But, if that does happen, the only sane solution to the issue, is to cut off the guides with the offending threads, and rewrap with a different spool of thread that does not have the issue. Hence, my suggestion to remove the spool of thread from the shop permanently, so that one does not grab the spool of defective thread and wrap some more guides with it.

------------------------------------

Also, after wrapping your guides, do you do an excellent job of "burnishing" the thread wraps? For myself, I have a plastic burnishing tool with a very smooth side on the tool. Then, when spinning the rod at a good clip, I use the wrapping tool to use significant pressure on each of the wraps to essentially burnish or "polish" the wraps, before applying the first coat of finish. After burnishing and before applying finish, be sure to look closely at each wrap under magnification and very bright lights for any defect or raised thread, or projecting tag ends on each and every wrap. If you discover any sort of defect, repair it now, before you apply your first coat and subsequent coats of finish.

Also, if the wraps have been finished more than a day or two before first applying finish, I like to "Tack off the wraps" using light tack blue painters tape to insure that there is no dust or anything else on the wraps. If dust, or bugs have settled on the wraps you don't want to have it beneath the finish on the thread wraps.

Summary:

1. Insure that you have no defects in your thread tension devices, what ever they may be.

2. Insure that you have no defects in the thread path that the thread travels after leaving the spool before getting to the rod.

3. Insure that the thread itself is not defective and forming fuzzies.

4. Insure that you have no projecting tag ends, or other defects in the actually wrapping of the guide foot itself.

5. Do an excellent job of burnishing the thread wraps and do a final inspection of each and every wrap under very bright light and at least 3x magnification for any possible defect.

6. If it has been days from the time that the guides have been wrapped before applying finish - insure that there is no contamination on any of the wraps - using what ever method you prefer to avoid trapping that contamination under the first and multiple coats of finish.

Best wishes.

Re: wrap epoxy feels rough

Posted by:

roger wilson

(---) Date: December 31, 2022 12:16PM

By the way for actual wrapping or final inspection, head band mounted high intensity lights can really aid in overall better rod building during many different aspects of the build.

Then, no matter where you are, you always have extremely bright illumination of everything that you are doing.

There are many many different models of hand band mounted lights on the market.

Pick one or more that work for you and use it whenever it is needed to provide more illumination on a particular object or for a particular task:

One example:

[ www.voltlighting.com]

Take care

Re: wrap epoxy feels rough

Posted by:

Kevin Fiant

(---) Date: December 31, 2022 01:17PM

El - feel your pain. Working on my first. No issues with fuzziness with thread itself but did have a fuzzy sticking out after pulling thru wrap tie off. Also noticed a couple specks of dust. I waited several days between wrapping and finishing so probably my issue there. Anyhow you are not alone on making some rookie mistakes

Re: wrap epoxy feels rough

Posted by:

Ernie Blum

(---) Date: December 31, 2022 01:54PM

Since nobody has mentioned it so far, perhaps it is considered taboo now for some reason. But if so, I haven't heard anything!

When trimming the thread and you somehow just miss a nice clean through and through cut, you can easily end up with the slightest strand that could wreak havoc upon the application of finish. Sometimes it's obvious, and sometimes you don't even know it's there until it's too late. Going back as far as the late eighties, I have always concluded my pre-finish prep by passing the flame of an alcohol lamp quickly around each wrap. Any fuzzy, apparent or inapparent, is quickly flashed away, as is any inapparent dust that may have settled prior to your epoxy application. Do NOT use a cigarette lighter, or you'll be wiping soot off your thread.

Re: wrap epoxy feels rough

Posted by:

David Baylor

(---.res6.spectrum.com) Date: January 02, 2023 12:26PM

I do as Mark described and make my over wrap of my pull through loop fairly long. About 10 to 15 wraps using size A thread. If I miss it and have a little bit of the tie off pop out I do as Ernie just outlined, and hit it with some flame. I understand what he is saying about using a lighter can cause soot on your thread, but I use a lighter and haven't noticed it causing any problem with finish epoxy or anything else. Just understand that you if you try to singe too much thread, it just makes a ball that will most likely show up in your finish.

Re: wrap epoxy feels rough

Posted by:

roger wilson

(---) Date: January 03, 2023 10:40AM

David,

If you are going to use a lighter, use a butane lighter that does not have any color in the flame.

No color, no smoke or soot.

[ www.amazon.com]

Re: wrap epoxy feels rough

Posted by:

Michael Danek

(---.adr01.alma.mi.frontiernet.net) Date: January 03, 2023 11:54AM

If one just holds the side of the flame close to the blank and rotate the blank the flame is not under the blank and never any soot.

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(50.233.0.---) Date: January 04, 2023 12:30PM

@ALL thank you very much for all of the feedback!

@ROGER I am using the Batson wrapper that has the spool tensioned down sideways with a wing nut and thread passed through a metal hoop. Honesty its making me wish I went with the CRB wrapper.

I don't think this device lends itself to smooth consistent tension.

I will follow those steps to check for issues, and if I wait to wrap I will masking tape off any dust etc. from the wraps.

@MICHAEL that makes sense, I think I'll go with that sideways lighter if need be. Do you do that when applying epoxy to keep it smooth or remove excess as well?

Edited 1 time(s). Last edit at 01/04/2023 12:30PM by El Bolinger.

Re: wrap epoxy feels rough

Posted by:

roger wilson

(---) Date: January 04, 2023 11:23PM

Ed,

Here is a picture of the thread holder and tensioner that I assembled, when I first began building rods many years ago. I have never found a need to use anything else, and it has worked perfectly all of the years and completed rods since.

Rod building tools do not have to be complicated.

[ www.rodbuilding.org]

The base is a piece of 1 inch thick nylon.

The thread holders are a simple steel rod pressed into a hole drilled into the base.

The vertical piece is a piece of oak trim.

The tension device is a simple double disk/spring device that works well. Note - on a new device, be sure that there are no flaws on the surfaces of the disk that create the tension. If necessary polish them with 1200 grit wet and dry sand paper for a mirror finish.

The thread comes off the thread spool and runs through a Fuji guide with a ceramic insert and then up to the tension device and then to the rod.

Since there is virtually no tension on the thread as it comes off the spool, there is little chance that the thread will be damaged when it runs through the Fuji guide on its way to the tension device.

Note:

With this system, I do NOT use metallic thread.

For metallic thread wraps, I simply take the appropriate length thread and use my hand to hold the thread as it is wrapped during a trim wrap. That way the metallic thread is not damaged.

I never use metallic thread for main wraps and thus does not present an issue for any of the rod building chores.

p.s.

If you don't have an alcohol burner, buy one, along with 98% pure denatured alcohol from the paint department of big box stores for fuel.

If you buy the alcohol from the drug store that is only 70% pure, you will have a visible flame that emits soot.

p.p.s.

For myself, for most of the time when I am working with thread wraps and finish and I need heat, I use my industrial heat gun. No flame, no soot and no fuel other than electricity from the wall outlet.

I keep the shop clean, so no issue with dust in the air being blown around by the heat gun.

Take care.

p.p.p.s

For the thread holder and tension device, I wrap on a rod bench that has a kitchen counter Formica top that is smooth and continuous. The wrapper bed that I use is a 10 foot long piece of aluminum channel.

When, rod building, the thread and its holder is behind the rod. I simply reach under the rod and as I wrap, I grasp the front pin on the thread holder to move it along as I wrap. There are no seams in the one piece 10 foot long wrapper bed, and no seams in the top of the rod bench. As a result, the thread is easy to move with no herky jerky movement for smooth wraps.

With this system, there is one spool of thread. I have never wrapped with more than one thread at a time. I have never found the need.

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(71.184.77.---) Date: January 06, 2023 11:22PM

@ROGER thanks, maybe I'll try to tinker around and see what happens - I have no wood working experience or anything like that building stuff, but I do like to tinker.

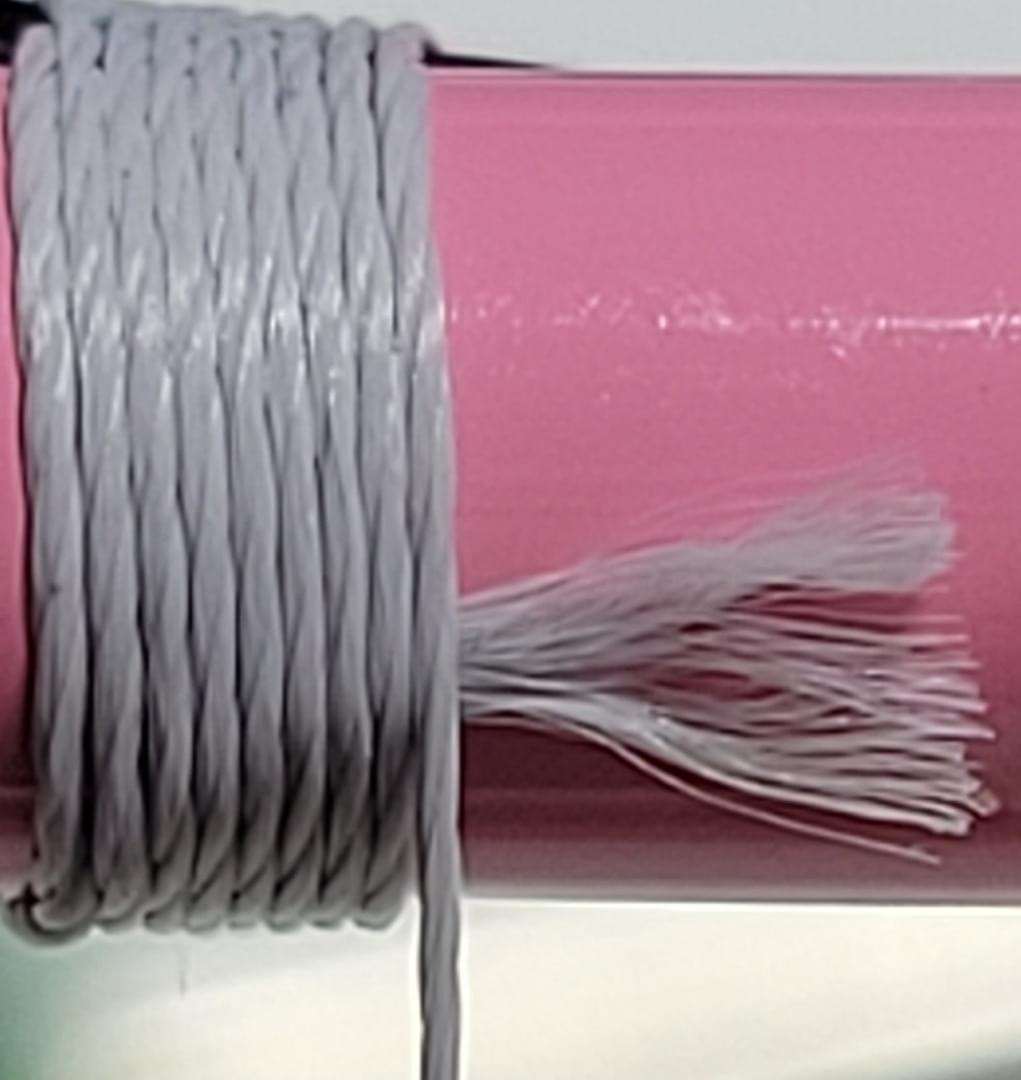

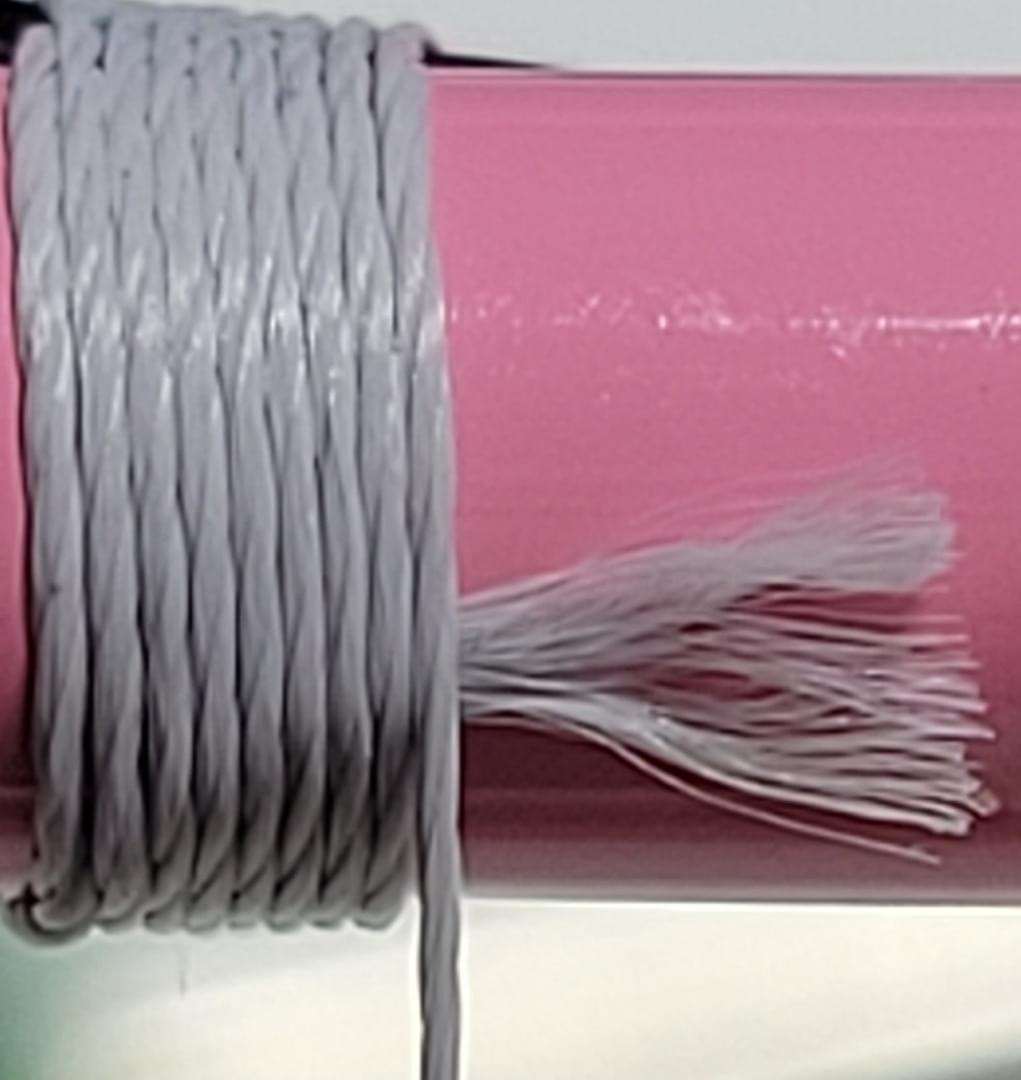

I thought maybe a picture would add some clarity to potential issues.

How do you avoid thread flare like this after a cut?

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(---.bstnma.fios.verizon.net) Date: January 07, 2023 12:28AM

Didn't think anybody would see, because I didnt so in posting again.

Re: wrap epoxy feels rough

Posted by:

Steven Paris

(---.37.17.98.dynamic.ip.windstream.net) Date: January 07, 2023 05:11AM

Twist your thread counter clockwise to tighten the weave of the thread before cutting.

Re: wrap epoxy feels rough

Posted by:

Norman Miller

(Moderator) Date: January 07, 2023 11:26AM

Can cut closer to the wrap. A little flare is not necessarily a bad thing, since when you over wrap you won’t get much of a tag bump. I use a pair of sharp, fine tipped scissors to cut my thread and don’t see the amount of flare you have in your picture.

Your closeup photo makes it look like you are using rope instead of wrapping thread.

PS - As others have mentioned above, I also insert the tie off loop early and after finishing the wrap I inset the tag end of the thread into the loop and pull the loop up to to the very edge of the wrap. Using sharp fine tipped scissors, I cut the tag end right up at the end of the loop. When you pull the loop through the tag end is pulled under the thread but not through it. This prevents any thread nubs and gives you a nice smooth finish. This method also save time when wrapping, since you don’t have to waste any time trying to clean up the thread nub.

Norm

Edited 1 time(s). Last edit at 01/07/2023 11:38AM by Norman Miller.

Re: wrap epoxy feels rough

Posted by:

El Bolinger

(71.184.77.---) Date: January 08, 2023 12:47AM

I took yalls advice and pulled thread tight to final wrap and clean cut no tension with no flare just above where the pull through was holding the thread and got this still.

And just to add I'm using Fuji NoCp

Edited 1 time(s). Last edit at 01/08/2023 12:52AM by El Bolinger.

Sorry, only registered users may post in this forum.

|